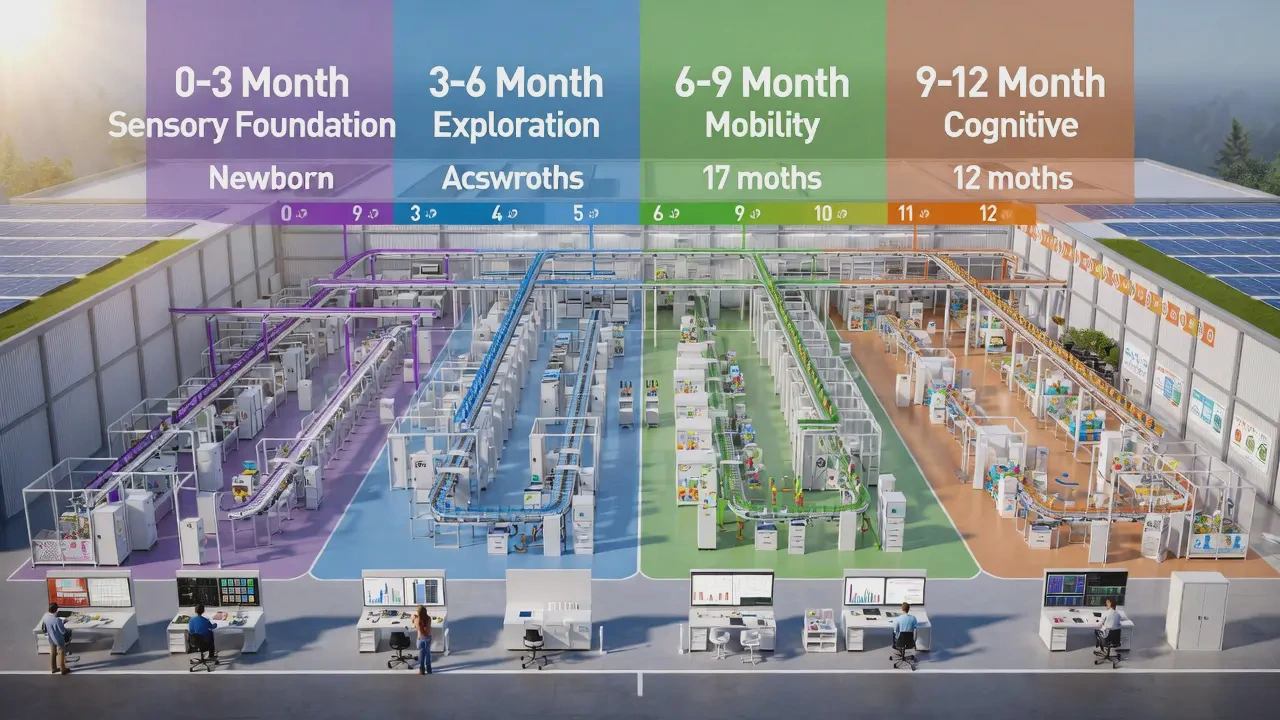

How to Manufacture Age-Specific Infant Toys: 0-12 Month Factory Guide 2024?

Professional Infant Toy Manufacturing: Month-by-Month Precision Production System for 0-12 Months

In today's competitive global toy market, true professional manufacturing has evolved from mass production to a refined model of precision manufacturing by age. As a specialized infant toy manufacturer focused on 0-12 months, we deeply understand how each month's unique developmental needs translate into specific manufacturing parameters. This article systematically elaborates on the complete manufacturing technology system, from newborn sensory toys to pre-toddler cognitive toys.

Professional Construction of the 0-12 Month Manufacturing System: From Theory to Practice

0-3 Months: Professional Standards for Sensory Foundation Period Manufacturing

The core challenge of newborn period manufacturing lies in balancing stimulation with safety. Products at this stage, as professional outputs of a sensory toys for infants factory, must meet strict standards.

Professional Manufacturing Parameter System:

Visual Stimulation Precision: Black-white-red combinations with contrast ≥85%, pattern edge sharpness controlled within 0.1mm tolerance

Auditory Safety Standards: Volume grading control (three levels: 50/55/60dB), frequency range 500-2000Hz

Tactile Development Design: Each product integrates at least 3 different textures, roughness Ra value gradient 0.8-3.2μm

Material Safety Protocols: All contact surface materials meet food-grade standards, migration element testing updated monthly

Quality Control System: As strict implementers of safe baby toy manufacturing standards 2024, we have established a three-layer detection mechanism—raw material batch testing, real-time production process monitoring, and 100% finished product safety verification.

3-6 Months: Manufacturing Technological Innovation for Exploration Development Period

When infants enter the 3-6 month stage, manufacturing focus shifts to supporting grasping development and cause-effect cognition. As a 3-6 month toys manufacturer, we implement the following innovations:

Grasping Optimization Manufacturing Technology:

Ergonomic Design: Handle diameter gradient 3.5-4.2cm, matching monthly hand development data

Material Combination Innovation: Outer layer medical-grade silicone (Shore A20-30) + inner layer antibacterial EVA foam

Weight Distribution Engineering: Lowered center of gravity design, base weighted 15-20% for enhanced stability

Motion Mechanism Optimization: Rotation/sliding component resistance precisely controlled within 0.5-1.5N range

Production Process Innovation: On the baby learning toys factory OEM production line, we have introduced a modular manufacturing system that allows rapid switching between different age product configurations, improving production efficiency by 30%.

6-9 Months: Manufacturing Engineering Breakthrough for Mobility Period

6-9 month crawling toys manufacturing requires addressing the dual needs of movement motivation and safety monitoring. As a crawling toys manufacturing specialist, our technical solutions include:

Precision Manufacturing of Motion Activation Systems:

Infrared Sensing Array: 32-point matrix layout, adjustable detection range 30-50cm

Response Time Optimization: From motion detection to feedback output ≤0.3 seconds

Speed Adaptation: Automatically adjusts toy movement rhythm based on infant crawling speed (0.2-0.5m/s)

Multi-layer Safety Protection: Physical limit + electronic braking + software protection triple mechanism

Durability Engineering: Through enhanced manufacturing processes on the motor skill toys production line, products can withstand over 10,000 drop tests (from 80cm height onto concrete floor).

9-12 Months: Advanced Manufacturing for Cognitive Breakthrough Period

9-12 month cognitive toys manufacturer face the precision manufacturing challenge of complex cognitive mechanisms. At this stage, brain development toys manufacturer need the following capabilities:

Cognitive System Integration Manufacturing:

Language Development Module: Dual audio chip supporting 8 languages, signal-to-noise ratio ≥80dB

Problem-Solving Mechanisms: Progressive difficulty system, from 3-step to 12-step problem complexity

Fine Motor Training: Component tolerance controlled within ±0.15mm, surface roughness Ra≤0.4μm

Social Interaction Design: Response delay gradient settings (immediate/short delay/long delay)

Safety Upgrades: As an educational toy factory with age certification, we implement a monthly safety upgrade plan—reviewing and updating safety protocols monthly to ensure compliance with the latest international standards.

Professional Manufacturing Facilities: Age-Segmented Production System

0-6 Month Specialized Manufacturing Center

Our 0-6 month manufacturing facilities adopt the following professional configurations:

Environmental Control Standards:

Cleanliness level: ISO Class 7 (10,000 class)

Temperature and humidity control: 22±0.5℃, 45±3%RH

Static protection: Workbench surface resistance 10^6-10^9Ω

Lighting system: 5000K color temperature LED, illuminance ≥1000lux

Specialized Equipment System:

High-precision Injection Molding Unit: 32-cavity mold, cycle time 18-22 seconds

Automatic Assembly Line: 6-axis robot, positioning accuracy ±0.02mm

Online Inspection System: Machine vision + laser measurement, inspection speed 120 pieces/minute

Packaging Automation: Automatic boxing + heat shrinking + labeling integration

6-12 Month Advanced Manufacturing Base

6-12 month product manufacturing requires more complex technical support:

Technical Upgrade Focus:

Automation Level: Increased from 75% to 92%

Quality Inspection Points: Increased from 12 to 28

Test Coverage: Functional test coverage reaches 100%

Traceability System: Unique ID for each product, full lifecycle tracking

Dynamic Evolution System of Safety Manufacturing Standards

Monthly Material Safety Database

As practitioners of 2024 safe baby toy manufacturing standards, we have established a dynamic safety database:

Monthly Safety Parameters:

Month Lead Content Cadmium Phthalates Formaldehyde Total Migration 0-3 <90ppm <75ppm <0.1% <15mg/kg <200ppm 3-6 <85ppm <70ppm <0.08% <12mg/kg <180ppm 6-9 <80ppm <65ppm <0.05% <10mg/kg <160ppm 9-12 <75ppm <60ppm <0.03% <8mg/kg <140ppm

Testing Frequency: Raw materials tested per batch, production process sampled every 2 hours, finished products 100% safety verified.

Structural Safety Evolution Path

In the developmental milestone toy production process, we implement a four-stage structural safety evolution:

Stage One (0-3 Months):

All edge radii ≥3mm

Surface smoothness Ra≤0.8μm

No removable small parts

Stage Two (3-6 Months):

Added anti-pinch design, gaps <5mm or >12mm

Introduction of flexible connection components

Sound outlet protective mesh

Stage Three (6-9 Months):

Anti-swallowing funnel design, minimum passage diameter ≥4.5cm

Safety guards for moving parts

Double insulation for electronic components

Stage Four (9-12 Months):

Interlock systems for complex mechanisms

Electrical safety isolation

Emergency stop mechanisms

Professional Manufacturing Process with Age Certification

Parallel International Standard Manufacturing System

As an educational toy factory with age certification, we achieve simultaneous compliance with multiple standards:

EU EN71 Manufacturing Adaptation:

Physical testing: Monthly updates to test parameters and standards

Chemical analysis: Established database of 62 hazardous substances

Age identification: Product labeling system precise to monthly segments

US ASTM F963 Manufacturing Upgrade:

Impact testing: Energy values increasing by 0.5J/month

Pull force requirements: Established age-pull force correspondence curve

Label specifications: Multi-language safety warning system

Australia/New Zealand Standard Integration:

AS/NZS ISO 8124 compliant manufacturing

Regional safety requirement integration

Southern hemisphere market adaptability adjustments

Certified Manufacturing Implementation Process

The certification process for how to manufacture month-specific infant toys includes seven key steps:

Requirements Analysis Phase (3-5 days)

Target age developmental characteristic research

Market safety standard investigation

Preliminary cost-benefit assessment

Technical Design Phase (7-10 days)

Age-appropriate engineering design

Safety protection system development

Manufacturing process route planning

Prototype Verification Phase (10-15 days)

Functional prototype manufacturing (3-5 versions)

Safety performance test verification

User experience optimization iteration

Small Batch Trial Production Phase (5-7 days)

Production line debugging (100-500 trial pieces)

Process parameter optimization

Quality stability verification

Certification Acquisition Phase (15-20 days)

Third-party laboratory submission and testing

Certification document preparation and organization

Audit rectification and improvement

Batch Production Phase (according to order plan)

Full capacity production initiation

Online quality monitoring

Continuous improvement implementation

After-sales Tracking Phase (ongoing)

Market feedback collection

Safety incident monitoring

Product improvement suggestions

Professional Solutions for Custom Infant Toys Production China

Three-Tier Custom Service System

As professional custom infant toys production China OEM suppliers, we provide three service levels:

Basic Customization Tier (production cycle +5-7 days):

Color schemes: 3 primary + 2 accent color standardized selection

Texture combinations: 5 standard texture configurations

Packaging design: Supports 3 language label systems

Minimum order quantity: 1,000 pieces

Professional Customization Tier (production cycle +10-15 days):

Functional modules: Custom function combinations within safety framework

Cultural adaptation: Pattern, character, story localization

Special needs: Premature infant adjustments, developmental support customization

Minimum order quantity: 500 pieces

Advanced Customization Tier (production cycle +20-30 days):

New developmental pathway design

Proprietary material development and application

Exclusive certification acquisition support

Minimum order quantity: 200 pieces

Customized Quality Control

In custom infant toys production, we implement customer-specific quality control plans:

Customer Quality Files:

Customized inspection standard development

Personalized testing item settings

Customized acceptance criteria

Dedicated quality reporting systems

Differentiated Manufacturing for Gender-Specific Toys

Professional Considerations for 10 Month Old Boy Toy Manufacturing

As a toys for 10 month old boy manufacturer, we focus on the following manufacturing characteristics:

Design Features:

Color preferences: Blue tones 60%, balanced distribution of red/yellow/green

Theme selection: Combination of vehicles, animals, sports elements

Action characteristics: Linear motion, rotation, impact feedback

Sound design: Lower frequencies, stronger rhythm sense

Manufacturing Optimization:

Structural reinforcement: Increased material thickness 15-20%

Durability testing: Impact test standards raised 20%

Packaging design: Concise and powerful, clear information

Technical Characteristics of 10 Month Old Girl Toy Manufacturing

As a toys for 10 month old girl supplier, we implement differentiated manufacturing strategies:

Design Differentiation:

Color schemes: Pink/purple tones 50%, mainly soft colors

Theme preferences: Animals, dolls, family scene elements

Interaction characteristics: Curved motion, gentle feedback, multi-step interaction

Sound characteristics: Higher frequencies, stronger melody

Manufacturing Features:

Surface treatment: Higher gloss, finer textures

Detail precision: Decorative element tolerance ±0.1mm

Packaging aesthetics: More graphic elements, warm design

Gender-Neutral Manufacturing Principles

Despite gender differences, we adhere to the following universal manufacturing principles:

Core Consistency:

Safety standards: 100% identical requirements

Developmental functions: Consistent core development objectives

Quality systems: Unified quality control standards

Material safety: Same material safety levels

Adjustable Differentiation:

Modular design allows rapid adjustments

Color system supports flexible configuration

Replaceable theme element design

Graded packaging system customization

Innovative Practices in Modern Baby Toy Production

Technological Upgrades in Modern Baby Toy Production

As a leader in modern baby toy production, we implement the following innovations:

Smart Manufacturing Technologies:

Digital Twin System: Virtual factory synchronized with actual production

AI Quality Control: Deep learning defect detection, accuracy 99.2%

Predictive Maintenance: Equipment failure warning 7 days in advance

Energy Management System: Real-time energy consumption optimization, 15% electricity savings

Material Innovation:

Bio-based Plastics: Current application ratio 35%, target 45%

Self-cleaning Surfaces: Photocatalytic coating technology

Temperature-sensitive Materials: Color changes with temperature, fever warning function

Antibacterial Materials: Silver ion/copper ion antibacterial technology

Sustainable Development Manufacturing System

Our modern baby toys production includes a complete sustainable system:

Environmental Management:

Carbon footprint tracking: Carbon emission labels on each product

Water resource circulation: 85% production water recycling

Waste management: Zero landfill target, 95% recycling rate

Energy optimization: Solar power covers 40% of demand

Social Responsibility:

Local employment: 90% of employees from local communities

Supply chain responsibility: All suppliers meet social responsibility standards

Community engagement: 1% of annual revenue for child development projects

Transparent manufacturing: Full production process traceable and visitable

Technical Framework for Professional Manufacturing Implementation

Four-Phase Project Management System

In 0-12 month infant toy manufacturing, we adopt rigorous project management:

Phase One: Technical Feasibility (5-7 days)

In-depth analysis of age-specific manufacturing feasibility

Technical route comparison and evaluation

Risk assessment and mitigation solutions

Precise cost-benefit calculation

Phase Two: Engineering Development (15-20 days)

Detailed engineering design (3D models + engineering drawings)

Process route development and optimization

Mold design and manufacturing

Production line configuration planning

Phase Three: Verification Implementation (10-15 days)

Prototype manufacturing and testing (3 iteration rounds)

Production line debugging and verification

Employee training and certification

Quality system establishment

Phase Four: Scale Production (according to plan)

Batch production initiation

Quality monitoring operation

Continuous improvement cycle

Market feedback integration

Precise Time Dimension Control

In the developmental milestone toy production process, time control is key to quality:

Material Shelf Life Management:

Plastic pellets: Must be used within 48 hours of opening

Silicone raw materials: Constant 25℃ storage, expiration labeling

Electronic components: ESD protection, first-in-first-out management

Packaging materials: Humidity-controlled storage (<60%RH)

Process Time Optimization:

0-3 month products: Injection molding cycle extended 15%

3-6 month products: Cooling time precisely controlled ±2%

6-9 month products: Assembly time increased 20%

9-12 month products: Testing time extended 25%

Monthly Evolution System for Quality Assurance

Monthly Quality Benchmark System

We have established a 0-12 month quality benchmark evolution system:

Monthly Detection Standard Updates:

New edition detection standards released on the 1st of each month

Parameter adjustments based on latest research findings

Testing method optimization integrating market feedback

Updates to international standard change requirements

Monthly Quality Data Analysis:

Statistical analysis of production quality data

In-depth analysis of market complaint data

Improvement measure effectiveness tracking and evaluation

Quality trend prediction and prevention

Age-Adapted Traceability Systems

In an educational toy factory with age certification, traceability systems are customized by age:

0-6 Month Product Traceability:

Raw material batch traceability

Production process parameter recording

Complete test data preservation

Packaging association information management

6-12 Month Product Upgrade:

Added functional test data

Expanded user feedback records

Enhanced repair service tracking

Improved lifecycle management

Technological Foresight for Future Manufacturing

Next Developments in Smart Manufacturing

As an explorer in modern baby toys production, we are advancing:

Deep AI Applications:

Personalized manufacturing: Customized products based on infant characteristics

Intelligent quality inspection: Multi-modal fusion detection technology

Predictive optimization: Process optimization based on big data

Autonomous decision-making: Intelligent scheduling of manufacturing systems

IoT Integration:

Equipment interconnection: Smart connection of entire production lines

Real-time monitoring: 24/7 production process monitoring

Remote maintenance: Cloud-based fault diagnosis and repair

Data-driven: Manufacturing decisions based on real-time data

Implementation Pathways for Personalized Manufacturing

In the field of custom infant toys production, we are exploring new directions:

On-Demand Manufacturing Systems:

Small batch rapid response: Minimum order 100 pieces

Personalized configuration: Online design tool support

Direct manufacturing: Direct sales model bypassing intermediaries

Intelligent inventory: Predictive replenishment systems

User-Participatory Manufacturing:

Design crowdsourcing: User participation in product design

Feedback integration: Real-time user feedback for manufacturing improvement

Community manufacturing: User community-driven product development

Open innovation: Partner collaboration for innovation

The essence of professional infant toy manufacturing is transforming developmental science into precise manufacturing engineering. At Guangxikangjamei, we don't just produce toys—we manufacture developmental support systems, safety guarantee systems, and intelligent growth partners. From newborn sensory toys to advanced cognitive development toys, we provide complete manufacturing solutions.

Contact our age-specific manufacturing specialists today to begin planning your professional infant toy project. Let's create exceptional products that not only meet current standards but define future standards.