Month-by-Month Infant Toy Manufacturing: 6-12 Month Production Guide 2024

Precision Month-by-Month Developmental Toy Manufacturing: A Professional Production Guide for 6-12 Month Products

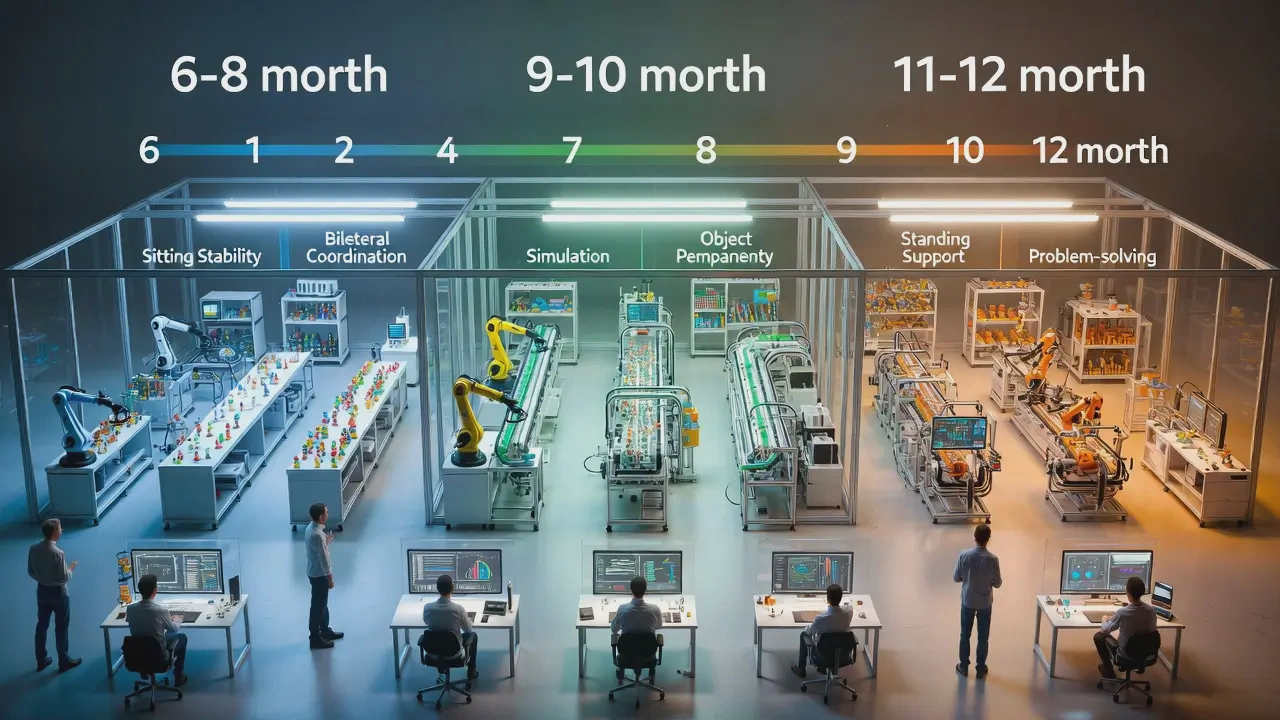

In the field of infant toy manufacturing, achieving true specialization means moving beyond generic design and entering the stage of precision manufacturing based on month-by-month development. From 6 month toy production to 10 month interactive toy manufacturer requirements, each stage demands unique design philosophies and manufacturing processes. This article provides professional manufacturers with a comprehensive technical guide covering everything from sensory toy manufacturing to motor skill toy production.

Month-Specific Manufacturing: From Theory to Practice

6 Months: Professional Manufacturing for the Sitting Stability Period

When infants begin to sit independently, 6 month toy production must focus on stability design. The key manufacturing priorities for this stage are:

Core Manufacturing Parameters:

Base diameter ratio: The golden ratio for toy base to height is 3:1

Center of gravity calculation: Using CAD software to simulate stability in different sitting postures

Material composition: 70% soft TPE combined with 30% hard ABS balances safety and durability

Bilateral coordination mechanisms: Symmetrical designs promote balanced left and right-hand development

Safety Evolution: In infant toy safety compliance manufacturing, 6-month products introduce the first layer of safety mechanisms—a progressive small parts management system that allows components >4cm in diameter, but only after passing 1,000 pull tests.

8 Months: Manufacturing Innovation for the Crawling Promotion Period

Crawling toy manufacturing must address the dual challenges of movement motivation and safety monitoring:

Motion Activation System Manufacturing:

Infrared sensing range: Set at 30-50cm to match crawling speed

Progressive speed adjustment: Gradually increasing from 0.2m/s to 0.5m/s

Sound and light feedback delay: Controlled within 0.3 seconds to establish immediate cause-effect cognition

Material Technology Breakthroughs: Under age-appropriate toy manufacturing standards, 8-month toys adopt a three-layer composite structure—outer antibacterial silicone, middle energy-absorbing EVA, inner support PP—meeting multiple needs of chewing, throwing, and impact.

10 Months: Precision Engineering for the Standing Preparation Period

10 month interactive toy manufacturer face the challenge of balancing functional complexity with operational simplicity:

Standing Assistance System Manufacturing:

Adjustable counterweight design: Allows 5 levels of weight adjustment (200g-500g)

Anti-tip angle: Automatic return within 15 degrees of tilt

Handle diameter gradient: Provides three specifications: 35mm, 40mm, 45mm

Cognitive Challenge Mechanisms: Cognitive development toy factory introduce modular puzzle systems at this stage, with each module manufactured independently before assembly, facilitating difficulty level adjustments and fault isolation.

Developmental Milestone Manufacturing Processes: Technical Implementation Pathways

Layered Manufacturing of Sensory Development Products

Sensory toy manufacturing is not a single process but rather precise integration of multiple senses:

Visual Hierarchy Manufacturing:

Contrast control: Decreasing from 90% contrast at 6 months to 40% at 12 months

Color introduction sequence: Following visual development order of red→yellow→blue→green

Pattern complexity: Increasing detail density by 10% each month

Tactile Matrix Production:

text

Month Texture Type Density(pcs/cm²) Hardness(Shore A) 6 Dotted 4 20 8 Linear 6 25 10 Mesh 8 30 12 Mixed 10 35

Auditory Development Manufacturing: Frequency range expands from 500-2000Hz at 6 months to 200-8000Hz at 12 months, increasing bandwidth by 500Hz each month.

Engineered Production of Motor Skill Toys

Motor skill toy production requires simulating the biomechanics of infant movement development:

Grasping Evolution Manufacturing:

Diameter progression: Increasing by 0.5mm monthly to match hand growth

Texture orientation: With-grain design reduces slipping, against-grain increases perception

Weight distribution: 30% heavier at distal end promotes forearm muscle development

Gross Motor Promotion Systems: Walking toy production line employs gyroscopic stabilization technology, automatically slowing down when tilt exceeds 20 degrees to ensure safe learning curves.

Specialized Manufacturing Facilities: Age-Segmented Production Line Design

6-8 Month Dedicated Production Line Configuration

Cleanliness level: 100,000-class clean room

Temperature control: 22±1℃ (preventing material property changes)

Humidity management: 45±5%RH (preventing static accumulation)

Inspection frequency: 3% product sampling hourly

Key Equipment:

Stability testing platform: Simulating 6 sitting posture states

Oral simulation testing machine: 60 chewing motions per minute

Visual tracking detector: Verifying attraction at 30cm distance

9-10 Month Production Facility Upgrades

Floor treatment: Anti-slip epoxy flooring (friction coefficient >0.6)

Lighting system: Adjustable color temperature LED (3000K-5000K)

Noise control: <65 decibels (protecting hearing development)

Special Processes: Introducing "fail-safe" manufacturing concepts in the developmental milestone toy production process—each moving component has an independent braking system.

11-12 Month Advanced Manufacturing Unit

Space requirements: 40% larger operation area (accommodating larger products)

Lifting equipment: Maximum load increased to 5kg

Quality gate setup: Increased from 3 to 5 inspection points

Innovative Technology: Adopting digital twin technology to test product-infant interaction patterns in virtual environments.

Compliant Manufacturing Systems: Multi-Standard Integration Practices

Age-Based Evolution of Safety Standards

Infant toy safety compliance manufacturing is not a static standard but a dynamic adaptation process:

Material Safety Gradient:

text

Month Migratable Elements(mg/kg) Phthalates(%) Formaldehyde(mg/kg) 6 Lead<90, Cadmium<75 <0.1 <15 8 Lead<85, Cadmium<70 <0.08 <12 10 Lead<80, Cadmium<65 <0.05 <10 12 Lead<75, Cadmium<60 <0.03 <8

Structural Safety Evolution:

6 months: All edge radii >3mm

8 months: Added anti-pinch designs (gaps <5mm or >12mm)

10 months: Introduced anti-swallowing funnel designs

12 months: Interlocking safety systems for complex mechanisms

Synchronous Manufacturing for International Standards

True baby developmental toys OEM requires parallel production meeting multiple standards:

EU EN71 Compliance Essentials:

Physical testing: Monthly updated test parameters

Chemical analysis: Quarterly submission system

Electrical safety: Applicable only to electronic toys

US ASTM F963 Manufacturing Adjustments:

Impact testing: Energy values adjusted monthly

Tension requirements: Different thresholds set by age

Label specifications: Age identification precise to months

Progressive Skill-Building Production Systems

Modular Manufacturing Architecture

The core of progressive skill-building toy production is reserving developmental space:

Hardware Interface Standards:

Connector types: Magnetic (6-8 months), snap-fit (9-10 months), threaded (11-12 months)

Expansion ports: Each toy reserves 2 standardized interfaces

Upgrade paths: Clearly marked "next development module"

Difficulty Adjustment Mechanisms:

Visible adjustments: Parent-operable obvious switches

Hidden advancements: Unlocking advanced functions with specific tools

Automatic adaptation: Sensors detecting infant capabilities for automatic adjustment

Personalized Production Possibilities

As professional infant toy production specialist, we offer three levels of customization:

Basic Customization (production cycle +1 week):

Color scheme adjustments (3 main colors + 2 accent colors)

Surface texture selection (5 standard options)

Packaging language customization (up to 3 languages)

Professional Customization (production cycle +2 weeks):

Functional module reorganization (maintaining core safety architecture)

Cultural element integration (patterns, characters, stories)

Special needs adaptation (premature infant adjustments, developmental support)

Full Customization (production cycle +4 weeks):

New developmental pathway design

Proprietary material development

Exclusive safety certification acquisition

Time Dimension Control in Manufacturing Quality

Monthly Age Calibration During Production

How to manufacture month-specific infant toys requires time verification at every stage:

Material Shelf Life Management:

Plastic pellets: Must be used within 72 hours of opening

Silicone raw materials: Constant temperature storage, 6-month validity

Textiles: Humidity-controlled storage to prevent property changes

Process Time Control:

Injection molding cycle: Adjusted cooling times based on age (+10% time for 6-month products)

Assembly rhythm: 12-month products allow 20% additional inspection time

Testing duration: Product testing time proportional to target age

Long-Term Performance Validation

True developmental toy manufacturer concern themselves with the entire product lifecycle:

Accelerated Aging Tests:

Temperature cycling: -10℃ to 50℃, 100 cycles

UV exposure: Equivalent to 6 months outdoor use

Mechanical fatigue: Simulating 12 months of daily use intensity

Developmental Effectiveness Verification:

Collaborating with child development institutions for:

Monthly usage observation

Skill progression recording

Safety incident tracking

Guangxikangjamei's Professional Manufacturing Solutions

Segmented Specialized Production Facilities

We possess industry-leading age-specific toy factory configurations:

6-Month Product Dedicated Line:

Capacity: 10,000 pieces daily

Precision: Dimensional tolerance ±0.3mm

Inspection: AI vision system 100% coverage

8-10 Month Integrated Production Line:

Flexible manufacturing: Quick changeover between different products

Modular design: Supports functional combination adjustments

Real-time monitoring: Data collection at each workstation

12-Month Advanced Manufacturing Center:

Technology integration: Mechanical, electronic, software coordination

Customization capability: Small-batch customized production

R&D linkage: Seamless connection between manufacturing and research

Quality Assurance Systems

Our identity as baby educational toy manufacturer is built on rigorous quality foundations:

Four-Level Inspection System:

Raw material inspection (batch testing)

Online inspection (each workstation)

Finished product inspection (100% coverage)

Developmental verification (monthly sampling)

Traceability Technology:

RFID full-process tracking

Blockchain quality records

Cloud data storage (10-year retention)

Sustainable Development Manufacturing

As responsible infant stimulation toy maker, we implement:

Eco-Friendly Manufacturing Practices:

Energy: 40% solar power supply

Water resources: 85% recycling rate

Waste: Zero landfill target

Material Innovation:

Bio-based plastic application: Currently reaching 35%

Recyclable design: All products disassemblable for recycling

Carbon footprint tracking: Carbon emission labels on each product

Implementation Roadmap: Launching Professional Manufacturing Projects

Phase 1: Monthly Age Positioning Analysis (1 week)

Target market monthly age distribution research

Developmental need gap identification

Competitive product technical analysis

Preliminary manufacturing plan development

Phase 2: Technical Solution Design (2-3 weeks)

Developmental goals and manufacturing parameter matching

Safety compliance pathway planning

Cost-performance balance point determination

Prototype manufacturing technical validation

Phase 3: Trial Production Validation (4-6 weeks)

Small-batch production (100-500 pieces)

Comprehensive laboratory testing

Actual usage observation

Manufacturing process optimization

Phase 4: Scale Manufacturing (8-12 weeks)

Production line debugging and validation

Quality control system establishment

Employee training and certification

Continuous improvement mechanism initiation

Success Case: Progressive Developmental Toy Series Manufacturing

Project Background

European client required a complete toy system covering 6-12 month developmental progression

Manufacturing Challenges

Monthly continuity: Smooth transitions between products

Safety evolution: Changing safety standards by age

Functional layering: Later products compatible with earlier toys

Solution

Platform-based manufacturing: Establishing a unified foundation platform

Modular design: Functional modules added monthly

Safety upgrade paths: Enhanced safety features month by month

Digital companion system: Manufacturing data supporting app development

Manufacturing Results

Development cycle: 14 weeks (30% shorter than traditional methods)

Product consistency: 98% accuracy in monthly age characteristics

Market acceptance: First-year sales exceeding expectations by 45%

Safety record: Zero recalls, complaint rate <0.1%

Future Manufacturing Trends: Integration of Intelligence and Precision

Digital Twin Manufacturing Technology

Virtual infant model testing

Real-time manufacturing process simulation

Personalized production prediction

Biometric Integration

Heart rate monitoring toy manufacturing

Emotion response system production

Automatic developmental progress recording

Sustainable Precision Manufacturing

On-demand production reducing waste

Material lifecycle management

Carbon-intelligent production scheduling

Global Compliance Manufacturing

Multi-standard parallel production systems

Rapid regional adaptability adjustments

Automated cross-border certification

The essence of professional manufacturing lies in understanding the time dimension of development. Each month's growth is not merely the passage of time but a leap in capability levels. At Guangxikangjamei, we translate this understanding into precise manufacturing parameters, rigorous safety controls, and continuous developmental support.

We don't just manufacture toys—we manufacture developmental tools, safety guarantees, and growth companions. From 6-12 month toy manufacturer to cognitive development toy factory, we provide complete solutions, not just products.

Contact our monthly manufacturing specialists today to begin planning your next developmental toy series. Let's create professional products that not only meet standards but define them.