Professional Educational Toy Manufacturing: Wooden Toys, Montessori Products & Sustainable Solutions

The Art and Science of Educational Toy Manufacturing: A Professional Perspective

Strategic Manufacturing Insights for the Modern Toy Industry

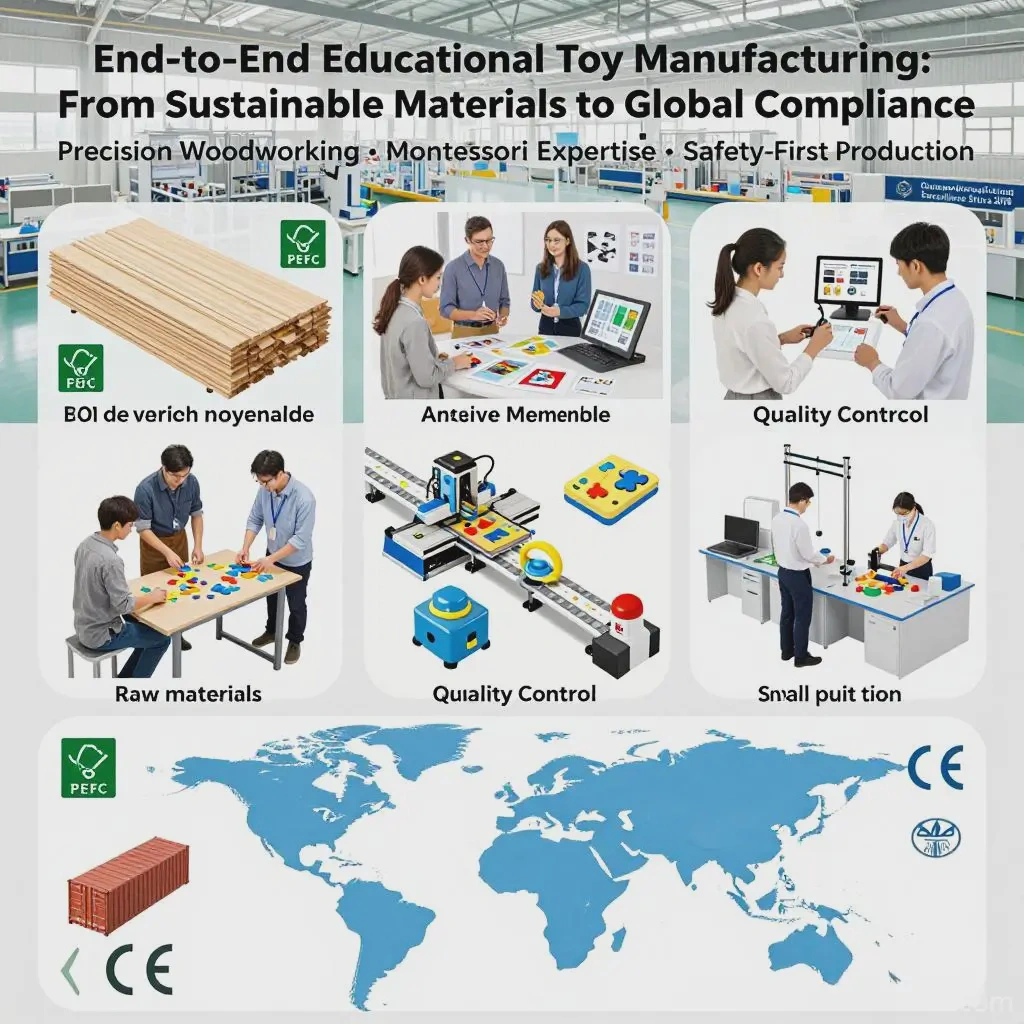

In the evolving landscape of children's educational products, discerning buyers seek more than just suppliers—they seek manufacturing partners who understand the intricate balance between educational value, safety compliance, and production excellence. When international businesses search for specialized manufacturing solutions, they're not merely looking for production capacity; they're seeking expertise in creating meaningful educational experiences through well-crafted toys.

The Complexities of Wooden Educational Toy Manufacturing

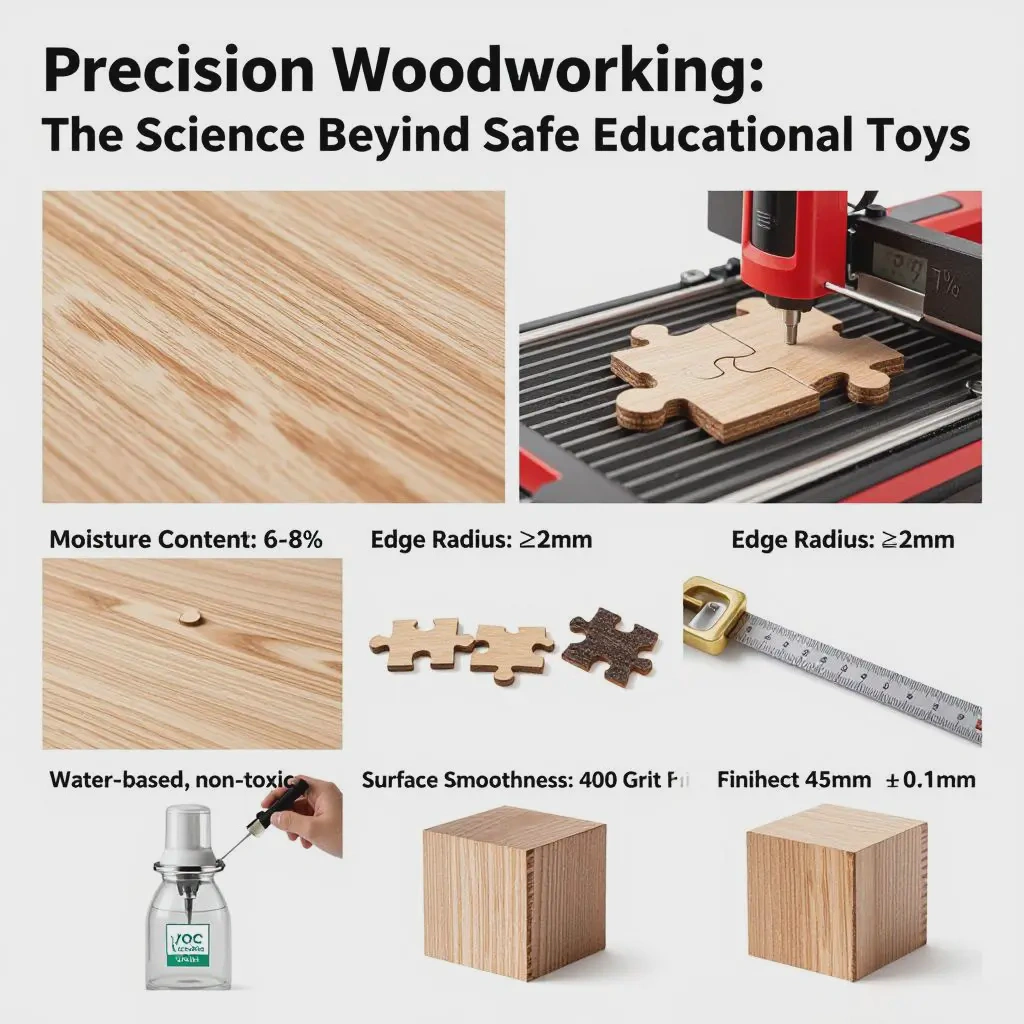

A proficient wooden educational toys manufacturer must navigate multiple considerations beyond basic woodworking. The selection of wood species directly impacts not only durability but also sensory characteristics—maple offers smooth surfaces ideal for grasping toys, while basswood allows for intricate carving in puzzle production. The moisture content of materials requires precise control, typically maintained at 6-8% to prevent warping or cracking in different climates. This technical understanding separates quality manufacturers from basic woodshops.

The manufacturing process for these educational tools involves specialized equipment calibrated for children's product safety. Edge rounding machines must maintain consistent radii of no less than 2mm, while sanding sequences progress through progressively finer grits to achieve surfaces smooth enough for sensitive skin. These production standards ensure that every educational block sets manufacturer delivers products that meet both tactile and safety expectations.

Montessori Toy Production: Philosophy in Manufacturing

Operating as a genuine Montessori toys factory requires understanding Maria Montessori's educational principles and translating them into manufacturing specifications. The Montessori emphasis on self-correction means that puzzle pieces must fit precisely enough to indicate errors, but not so tightly as to frustrate young learners. This balance demands manufacturing tolerances within 0.5mm—a precision that challenges even experienced woodworkers.

The production of best Montessori toys for 18 month old manufacturing focuses particularly on size and proportion. Materials must be large enough to prevent choking hazards (typically exceeding 3cm in diameter), yet small enough for developing hands to manipulate. Weight considerations become crucial—materials must feel substantial enough to provide sensory feedback, but light enough for toddlers to lift and explore independently.

Precision in Puzzle and Block Production

The specialized field of puzzle blocks production combines artistic design with engineering precision. Each puzzle component requires attention to grain direction to ensure structural integrity, while interlocking mechanisms demand tolerances that accommodate natural wood expansion in varying humidity conditions. Advanced manufacturers utilize computerized nesting software to optimize material usage, reducing waste while maintaining design integrity.

For educational block sets manufacturer, geometric accuracy becomes paramount. Blocks must maintain perfect 90-degree angles and consistent dimensions to support mathematical learning objectives. Modern production facilities employ laser measurement systems that verify dimensions to within 0.1mm, ensuring that block sets support spatial reasoning development effectively.

Sustainable Practices in Eco-Friendly Manufacturing

An authentic eco-friendly children's toys manufacturer implements sustainability throughout the production chain. This begins with FSC-certified wood sourcing, extends to water-based, non-toxic finishes, and includes energy-efficient manufacturing processes. The most advanced facilities now utilize solar power and closed-loop water systems, reducing their environmental footprint while maintaining production quality.

Waste management represents a critical area where sustainable manufacturers excel. Wood scraps become smaller products or biomass fuel, while sawdust finds application in composite materials or local agriculture. Packaging solutions increasingly incorporate recycled materials and minimalist designs that reduce shipping volume and materials use.

Specialized Production: Nativity Sets and Advent Calendars

A dedicated wooden nativity sets factory balances artistic craftsmanship with cultural sensitivity. Production teams require training in religious symbolism and cultural traditions to ensure appropriate representation. The manufacturing process often combines machine precision for repetitive elements with hand-finishing for unique character pieces, creating products that honor tradition while ensuring consistent quality.

The specialized field of advent calendar toy production presents unique manufacturing challenges. Each calendar requires 24-25 compartments that maintain structural integrity while allowing easy access. Safety considerations become particularly important, as small doors and moving parts must withstand repeated use without creating pinch points or splinter risks. Quality manufacturers develop specialized hinge and closure systems that balance durability with child-friendly operation.

Customization and Private Label Manufacturing

The growing demand for private label educational toys reflects market differentiation strategies. Successful private label partnerships begin with comprehensive design consultations, where manufacturers help clients translate educational goals into manufacturable designs. This collaborative process often includes material recommendations, safety assessments, and production feasibility studies before any prototyping begins.

For businesses seeking custom wooden toys manufacturer services, the development process typically follows several stages. Initial concept discussions focus on educational objectives and target age groups, followed by material selection consultations that balance aesthetics, durability, and safety. Prototyping phases allow for hands-on evaluation and refinement before final production specifications are established.

OEM Manufacturing Excellence

Professional OEM Montessori toy production relationships thrive on clear communication and shared standards. Successful OEM partnerships establish detailed quality specifications covering materials, dimensions, finishes, and safety requirements. Regular production audits and sample testing ensure consistent adherence to these standards throughout the manufacturing relationship.

The manufacturing of specialized products like custom advent calendar manufacturing requires particular attention to detail. Each calendar component must align perfectly, doors must open smoothly, and compartments must accommodate the intended contents without excessive space that could lead to shifting during shipping. Experienced manufacturers develop jigs and fixtures specifically for calendar production, ensuring consistency across production runs.

Quality Assurance in Educational Toy Manufacturing

Modern toy manufacturing employs multi-layered quality assurance systems. Incoming material inspections verify wood quality, moisture content, and safety certifications. Production monitoring includes dimensional checks at multiple stages, with particular attention to critical safety elements like edge rounding and surface smoothness.

Final inspections for educational toys involve both technical measurements and practical testing. Products undergo simulated use testing, checking for durability and functional performance. Safety verification includes small parts testing, mechanical hazard assessment, and material safety confirmation through independent laboratory testing when required.

Global Compliance and Market Adaptation

International toy manufacturers must maintain current knowledge of global safety standards. European EN71 requirements, North American ASTM standards, and various Asian market regulations each have specific provisions that affect design and manufacturing decisions. Successful manufacturers maintain comprehensive compliance databases and often employ dedicated regulatory specialists to ensure ongoing compliance.

Cultural adaptation represents another dimension of international manufacturing. Design elements, color preferences, and educational approaches vary across markets, requiring flexible manufacturing approaches. The most successful manufacturers develop modular production systems that allow for efficient customization to meet regional preferences while maintaining core quality standards.

The Future of Educational Toy Manufacturing

Innovation continues to shape the industry, with several emerging trends affecting manufacturing approaches. Digital integration represents a growing area, with manufacturers exploring ways to combine traditional wooden toys with digital learning elements while maintaining the tactile benefits of physical manipulation.

Advanced materials offer new possibilities, with developments in sustainable composites and enhanced surface treatments. Manufacturing technologies continue to evolve, with automation increasingly handling repetitive tasks while skilled artisans focus on design refinement and quality oversight.

The trend toward eco-friendly children's toys manufacturer practices continues to gain momentum, with consumers increasingly valuing transparency in material sourcing and production methods. Manufacturers who can clearly communicate their sustainability practices while maintaining competitive pricing and quality standards will likely lead market development in coming years.

Selecting a Manufacturing Partner

When evaluating potential manufacturing partners, experienced buyers consider several key factors. Technical capabilities should align with product requirements, while quality systems must demonstrate consistent performance. Communication effectiveness often determines project success, particularly for custom wooden toys manufacturer relationships where ongoing collaboration is essential.

Production flexibility represents another critical consideration, particularly for businesses with seasonal products or evolving product lines. The ability to scale production efficiently while maintaining quality standards separates exceptional manufacturers from adequate ones.

Ultimately, the most successful manufacturing partnerships balance technical excellence with collaborative spirit. Manufacturers who understand both the craft of toy making and the educational purposes their products serve create the most valuable partnerships for brands committed to children's development through thoughtful play.