Professional Educational Toy Manufacturing Guide | Wooden Toys & Developmental Products Production

Professional Educational Toy Manufacturing: A Comprehensive Guide

Connecting Craftsmanship with Child Development in Modern Manufacturing

In today's educational toy manufacturing landscape, truly professional manufacturers must transcend traditional production boundaries and integrate pedagogical principles into their manufacturing DNA. As a wooden educational toys manufacturer, our responsibility extends beyond simply producing toys—we create tools that actively support children's developmental journeys. This professional positioning demands that we simultaneously serve as craftspeople, educational specialists, and safety experts.

The Professional Dimensions of Developmental Toy Production

As a developmental toy production expert, we must understand how developmental needs at different age stages translate into specific manufacturing specifications. For instance, toys designed for toddlers require particular size ratios—grasping components typically should measure 3-4 centimeters in diameter, which isn't merely a safety requirement but a developmental necessity. For products supporting fine motor development, component weight distribution requires precise calculation to allow children successful operation while receiving appropriate feedback.

Manufacturing products to safe children's toys factory standards requires safety testing that exceeds conventional requirements. Our quality system includes durability testing that simulates real-world usage scenarios, particularly for products young children will repeatedly mouth. Material selection must not only meet chemical safety standards but also consider how tactile temperature and surface texture impact sensory development.

Specialized Requirements for Montessori Toy Manufacturing

Becoming a genuine Montessori toy manufacturing specialist means deeply understanding Maria Montessori's educational principles and translating these principles into concrete production standards. For example, self-correction functionality requires puzzle component tolerances to be controlled within 0.3-0.5mm—sufficiently tight to provide feedback, yet not so tight as to create frustration. Color selection must be based on educational purposes rather than aesthetic appeal alone, with contrast and saturation aligned with developmental visual requirements.

Regarding material treatment, natural wood grain direction requires careful planning to ensure structural integrity during long-term use. Surface finishes shouldn't completely mask wood's natural texture, as tactile feedback constitutes an essential component of Montessori education. Our craftspeople receive specialized training to understand the educational purpose behind every cut and plane.

Precision Craftsmanship in Wooden Block Manufacturing

Engaging in wooden block manufacturing appears simple but is actually filled with technical challenges. Mathematical precision forms the foundational requirement—right angles must be accurate to 90 degrees, with side length errors not exceeding 0.2mm. True professionalism, however, lies in understanding how this mathematical precision translates into educational value: dimensional proportional relationships support spatial cognitive development, while weight consistency helps establish physical concepts.

Our production process includes advanced wood drying technology, ensuring moisture control between 6-8%—the key to preventing warping and cracking. Edge treatment employs a multi-stage sanding process, gradually refining from 60 to 400 grit to create surfaces that are both safe and provide appropriate tactile feedback. This attention to detail distinguishes professional manufacturers from ordinary producers.

Complex Considerations in Educational Puzzle Production

In the field of educational puzzle production, every design decision carries educational purpose. Puzzle difficulty gradient design must be based on cognitive development theory, progressing from simple whole segmentation to complex partial combination. Image selection must support conceptual development, with everything from concrete animal images to abstract geometric patterns reviewed by educational specialists.

We use specially developed software to optimize cutting paths, maximizing material utilization while ensuring puzzle functionality. Connection point design must balance multiple factors: sufficiently sturdy to guarantee user experience, yet with appropriate "tightness" to support hand strength development. For younger users, we additionally design gripping aids, all of which must be planned during initial manufacturing stages.

Professional Operations of a Developmental Game Factory

Operating a developmental game factory requires systematic professional knowledge. Game mechanism design must be based on developmental psychology, ensuring appropriate challenge-ability matching. Interaction relationships between components require repeated testing to guarantee educational goal achievement. For instance, our cooperative game designs encourage social skill development, requiring special manufacturing considerations—components must be sufficiently engaging to promote sharing, yet not so unique as to cause disputes.

Production processes require flexibility to accommodate different games' unique requirements. We've established modular production systems enabling rapid switching between game types while maintaining quality control. Testing procedures include educational effectiveness evaluation—we collaborate with early childhood education specialists to ensure each game achieves its stated developmental objectives.

Professional Responsibility in Special Needs Toy Manufacturing

As a special needs toys manufacturer, our work carries particular significance and responsibility. Product design must be based on deep understanding of special needs, typically requiring close collaboration with therapists and special education teachers. Material selection must consider additional safety factors, such as reducing allergy risks and avoiding textures that might cause discomfort.

We develop specialized product lines for different special needs, with each product undergoing actual testing with target user groups. Manufacturing processes require higher quality control standards, as many users may be more sensitive to product defects. Packaging and instructions also require special consideration, including communication support symbol systems and clear visual guidance.

Collaborative Models in Custom Wooden Toy Production

In custom wooden toy production projects, we provide not only manufacturing services but professional consultation. Beginning at the design stage, we help clients understand manufacturing feasibility, safety requirements, and cost-effectiveness balance. Material selection consultation includes demonstrating how different wood characteristics affect final products' educational value and usage experience.

Our customization process involves multiple prototype iteration stages, each with clear educational objective verification. Through close collaboration with clients, we transform their educational philosophies into manufacturable, marketable physical products. This deep collaboration distinguishes us fundamentally from simple contract manufacturers.

Comprehensive Support for Private Label Educational Toys

Developing private label educational toys requires manufacturers to possess comprehensive capabilities. We provide clients with full-spectrum support from market analysis to product design. Brand consistency manifests not only in visual design but, more importantly, in educational philosophy implementation. We help clients establish complete educational product systems, ensuring logical relationships and developmental continuity between different products.

Quality assurance systems must adapt to different brand requirements while maintaining our consistent high standards. Packaging and promotional materials must also align with product philosophies—we provide complete brand support materials including educational guides and activity suggestions.

Precise Collaboration in OEM Toy Manufacturing

In OEM toy manufacturing partnerships, success depends on precise technical integration and continuous quality management. Starting from clients' brand standards, we establish detailed technical specifications and quality control points. Each key production parameter undergoes real-time monitoring and recording, ensuring consistency between production batches.

Our OEM services particularly emphasize intellectual property protection, establishing strict information security systems. Simultaneously, we provide continuous technical improvement suggestions, helping clients' products maintain competitive advantages in dynamic markets. This long-term partnership perspective elevates our OEM relationships beyond simple buyer-seller transactions.

Innovative Research in Custom Developmental Products

Developing custom developmental products requires combining innovative thinking with rigorous execution. We collaborate with educational institutions and research organizations to transform the latest developmental theories into practical products. The innovation process includes multiple testing phases, from laboratory testing to small-scale field testing, ensuring products are both effective and practical.

Manufacturing processes require flexibility to accommodate innovation demands—we've established specialized rapid prototyping capabilities and small-batch production systems. Simultaneously, we emphasize innovation manufacturability, ensuring excellent designs can transform into high-quality, affordable products.

Technical Foundations of Manufacturing Professionalism

Deep Application of Material Science

Our material selection is based on thorough research and testing. Each wood type undergoes rigorous screening, considering not only aesthetics and cost but, more importantly, educational value and safety performance. We've established a complete material database recording each material's physical characteristics, processing properties, and long-term performance.

Surface treatment technology continues evolving—we now use coatings and oil finishes based on natural ingredients that both protect wood and preserve its natural characteristics. For products requiring special sensory effects, we've developed specialized treatment processes creating unique tactile and visual experiences.

Multi-Layered Quality Control Systems

Our quality assurance system comprises three levels: preventive control, process control, and final inspection. Preventive control begins with supplier management, ensuring all raw materials meet our strict standards. Process control includes real-time monitoring of each production stage, with any deviations immediately triggering corrective actions.

Final inspection not only checks product compliance with technical specifications but, more importantly, verifies educational functionality. We collaborate with independent educational specialists for regular product effectiveness evaluations—this feedback mechanism continuously drives our quality improvement.

Sustainable Manufacturing Practices

As responsible professional manufacturers, we integrate sustainability into every decision. Our wood comes exclusively from certified sustainable sources, with energy and water usage in production processes optimized. Waste management approaches near-zero waste levels, with wood chips and scrap materials finding appropriate reuse pathways.

We also actively participate in community and educational projects, returning portions of profits to child development initiatives. This comprehensive sense of responsibility represents the social value inherent in professional manufacturing.

Professional Development for the Future

The educational toy manufacturing industry is experiencing rapid development, with new technologies and concepts continuously emerging. As professional manufacturers, we require continuous learning and innovation. We're exploring how digital manufacturing technologies can integrate with traditional craftsmanship to create more precise, personalized products.

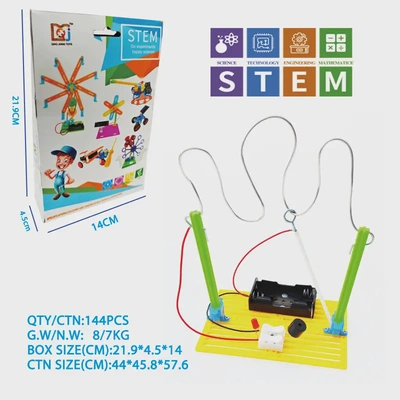

Simultaneously, we monitor global educational trend changes, adjusting our product strategies and service models. Whether responding to STEM education's rise or the growing importance of inclusive design, we're prepared to address these changes with professional capabilities.

True professionalism manifests not only in technology and craftsmanship but, more fundamentally, in commitment to educational missions and genuine care for child development. This constitutes our core value as educational toy manufacturing experts and the foundation for establishing long-term collaborative relationships with clients.