ASTM F963 vs. ISO 8124: Which Toy Safety Standard Rules Your Market?

ASTM F963 vs. ISO 8124: Which Toy Safety Standard Rules Your Market?

For toy manufacturers and brands aiming for global reach, navigating the labyrinth of safety standards is a fundamental business challenge. Two names stand at the forefront: ASTM F963, the mandatory benchmark for the United States, and ISO 8124, the foundational international suite of standards adopted or adapted by countless countries worldwide. Choosing the wrong compliance path isn't just an administrative error—it can lead to costly recalls, blocked shipments, and damaged reputations. This guide provides a clear, side-by-side comparison to help you determine which standard—or combination—rules your target market and how to build a robust, efficient compliance strategy.

If your primary market is the USA, compliance with ASTM F963 is a legal requirement under the Consumer Product Safety Improvement Act (CPSIA). For markets outside the USA, ISO 8124 is the critical starting point, though you must often meet its regional derivatives (like EN 71 in Europe or GB 6675 in China). For global sales, a strategy that understands and integrates the strictest clauses from both is essential.

While both standards share the common goal of protecting children, their paths diverge in critical areas of enforcement, specific test methods, and chemical requirements. Understanding these nuances is key to efficient product development and market access. Let’s break down the comparison into four decisive questions every toy business must answer.

Market Access: Which Standard is Mandatory and Where?

Before diving into technical specifics, the most critical distinction lies in legal authority and geographical application. Your compliance obligation is dictated first by the markets you intend to enter.

ASTM F963 is law in the USA. ISO 8124 is a globally recognized framework adopted into national regulations worldwide. You don't choose one over the other based on preference; you follow the rules of your destination market.

ASTM F963-17 (with its most recent updates) is a federally mandated standard in the United States under the CPSIA. Toys cannot be sold in the U.S. without complying. ISO 8124 is a series of standards published by the International Organization for Standardization. Its power comes from being incorporated into national laws. For example:

European Union: The Toy Safety Directive (2009/48/EC) mandates the EN 71 series, which is harmonized with but not identical to ISO 8124.

China: GB 6675 is essentially the national adoption of ISO 8124, with specific modifications.

Canada, Australia, Japan: Each has regulations that align closely with ISO 8124 principles but have unique national requirements.

Bottom Line: Selling to the U.S.? You must meet ASTM. Selling internationally? You start with ISO 8124, but must confirm the specific national standard in your target country.

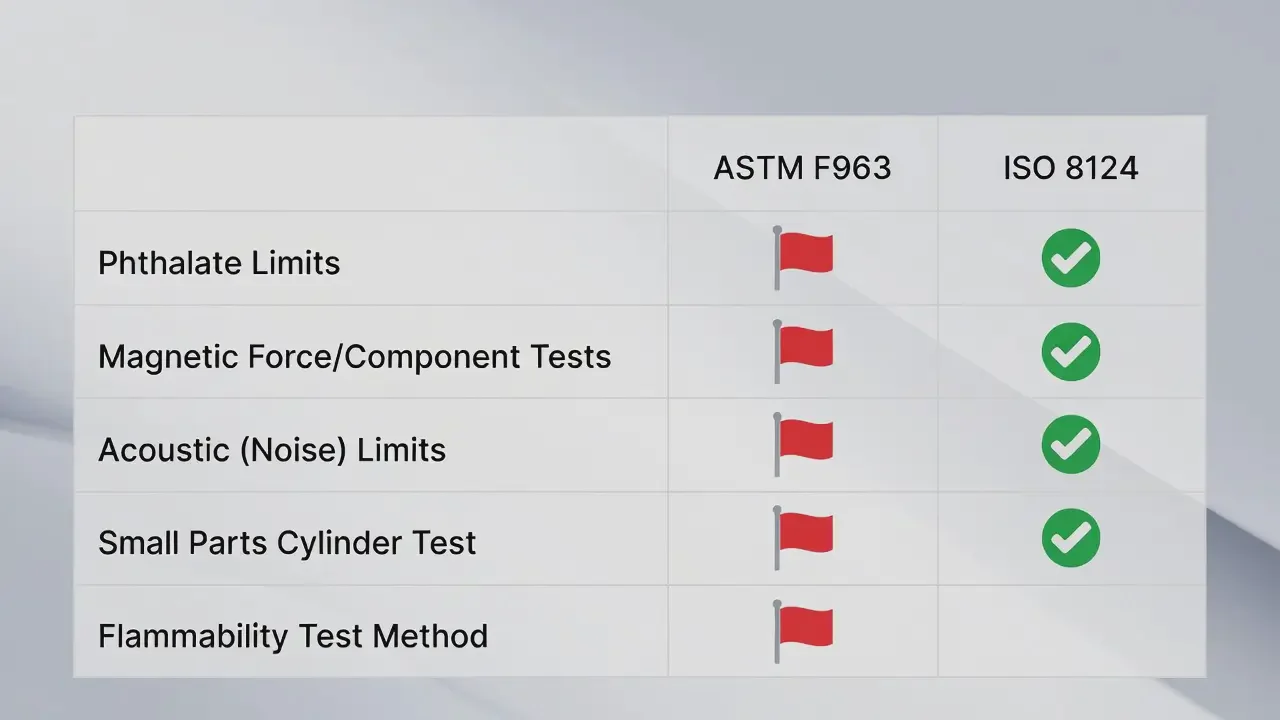

Key Test Differences: Where Do ASTM and ISO Diverge Most?

At their core, both standards address physical/mechanical, flammability, and chemical hazards. However, devilish—and crucial—details lie in the specific limits, test methods, and scope of these requirements.

Major differences exist in chemical restrictions (like phthalates), magnetic component requirements, and acoustic safety limits. ASTM F963 often has more stringent or detailed requirements for the U.S. market.

Chemical Safety (Phthalates): ASTM F963 references the CPSIA ban on eight specified phthalates in children's toys and child care articles. ISO 8124-5 aligns more closely with EU REACH, restricting fewer phthalates initially but within a potentially broader scope of "all toys." The list and limits are not identical.

Magnetic Hazards: ASTM F963 has particularly rigorous requirements for powerful small magnets. If a magnet fits into the small parts cylinder and has a flux index ≥ 50, it must not separate from the toy under specific use and abuse tests. ISO 8124-1 addresses magnetic toys but the U.S. requirements are often considered among the world's strictest.

Physical & Mechanical: The small parts cylinder (31.7mm diameter to prevent choking) is universal, but related tests like torque, tension, and drop tests can have different parameters, forces, or pass/fail criteria.

Acoustics: Sound level limits differ. ASTM F963 provides distinct limits for "close-to-the-ear" toys and "other toys," with impulse noise requirements. ISO 8124-1 has different threshold values and measurement protocols.

Cost & Complexity: Which Compliance Path is More Efficient?

Sub-heading 3 Opening Paragraph

Compliance isn't free. The cost and complexity of testing and certification are significant factors in product development. Is one standard inherently more expensive or simpler to meet than the other?

There is no simple "cheaper" option. Cost is driven by the strictest requirement your toy must meet. A product designed from the start to satisfy the most demanding clauses of both standards is often more cost-effective in the long run than retrofitting for a new market.

Testing Costs: Laboratory fees depend on the number of tests, materials, and colors. A toy requiring testing for eight phthalates (ASTM/CPSIA) plus additional substances for EU REACH will incur higher chemical testing costs. Similarly, if both acoustic test methods are required, both must be paid for.

Complexity & "The Hybrid Product": The real cost amplifier is managing a product with different material specifications for different markets. For instance, using plasticizer "A" for the U.S. version and plasticizer "B" for the international version doubles your quality control, inventory, and supply chain complexity. Designing a single product to pass the strictest requirements from all target markets (a "global grade" specification) minimizes this hidden cost.

Certification & Documentation: The U.S. requires a Children’s Product Certificate (CPC) based on ASTM F963 testing. The EU requires a Technical File and a Declaration of Conformity (DoC) based on EN 71 (derived from ISO). Managing separate documentation streams adds administrative overhead.

The Global Game: How Can You Navigate Both Standards Successfully?

For businesses with global ambitions, viewing ASTM and ISO as an "either/or" choice is a strategic mistake. The winning approach is an integrated compliance strategy that treats them as interconnected parts of a single product safety plan.

Success requires "designing up" to the highest benchmarks, conducting strategic "one-test, multiple-report" lab programs, and maintaining impeccable material and supply chain control.

Implement this four-step strategy:

Start with a Global Spec: During the design phase, create a single technical specification that mandates compliance with the strictest version of every applicable requirement from ASTM, ISO, EN, and other target markets. This makes your base product inherently compliant everywhere.

Leverage Laboratory Expertise: Partner with an accredited third-party lab experienced in both U.S. and international standards. They can often perform combined testing, where a single set of physical/mechanical tests on a sample can be evaluated against both ASTM and ISO criteria, generating separate reports for each market—saving time and sample costs.

Master Material Compliance: This is the cornerstone. Maintain a Declared Substances List (DSL) or Integrated Material Compliance Sheet for every component. This document should verify that all materials meet the chemical restrictions of all target regulations (CPSIA, REACH, etc.) from the outset.

Centralize Documentation: Use a compliance management system to house all test reports, certificates, material declarations, and technical files. This ensures you can swiftly generate the correct documentation (CPC for U.S., DoC for EU, etc.) for any shipment or audit.

Conclusion

Navigating the landscape of ASTM F963 and ISO 8124 is less about picking a winner and more about understanding a dual-language requirement for global business. ASTM F963 is your non-negotiable ticket to the U.S. market, a detailed, legally-enforced standard with specific stringent clauses. ISO 8124 provides the essential international framework, but its real-world application is through national adoptions like EN 71 or GB 6675.

The most efficient and safe path forward is not to comply with the minimum, but to "design up" to the highest global benchmarks from the start. By integrating the strictest requirements on chemicals, magnetics, and physical safety into a single product specification and leveraging strategic testing partnerships, you can streamline compliance, reduce long-term costs, and unlock seamless access to the world's largest toy markets. In the realm of toy safety, building to the highest standard isn't just good ethics—it's smart, scalable business.