Cost Pressures and Raw Material Volatility: How Can Educational Toy Brands Protect Their Margins?

Cost Pressures and Raw Material Volatility: How Can Educational Toy Brands Protect Their Margins?

For educational toy brands, the mission is noble: to create products that spark curiosity and fuel development. But the current business landscape is fraught with challenges that threaten this mission at its financial core. Soaring costs for plastics, lumber, and electronic components, coupled with persistent supply chain instability and shipping delays, are creating a perfect storm that relentlessly squeezes profit margins. In this environment, simply raising prices is a blunt instrument that risks alienating value-conscious parents. The pressing question for leaders in this space is no longer if they need to act, but how they can strategically and sustainably defend their business's financial health.

Protecting margins in today's market requires a move beyond reactive price hikes. It demands a proactive, multi-pronged strategy that combines intelligent product design, resilient supply chain management, strategic pricing, and innovative business models. The goal is to build a brand that is both financially robust and delivers undeniable value to its customers.

Navigating this squeeze successfully means addressing it from every angle. Let's explore the concrete strategies that forward-thinking educational toy companies are deploying to not just survive, but thrive.

What Are the Primary Forces Squeezing Educational Toy Margins?

To formulate an effective defense, you must first understand the multifaceted nature of the attack. Margin erosion is rarely caused by a single factor; it's the cumulative effect of several converging pressures that impact both the cost of goods sold (COGS) and operational expenses.

The primary forces can be categorized into Input Cost Volatility, Logistical & Operational Pressures, and Intensified Market Competition. Each category presents unique challenges that require tailored responses.

Input Cost Volatility is the most direct hit. Prices for key materials like ABS plastic, sustainably sourced wood, and microchips are subject to geopolitical, environmental, and market demand shocks. Logistical & Operational Pressures include elevated global shipping freight rates, increased warehousing costs, and the rising expense of mandatory safety certifications and compliance testing (like CPSC, CE, UKCA). Finally, Intensified Market Competition comes from both low-cost generic manufacturers and the sheer marketing power needed to stand out on crowded digital shelves like Amazon. This trifecta means brands are paying more to make and move products, while facing tougher battles to sell them.

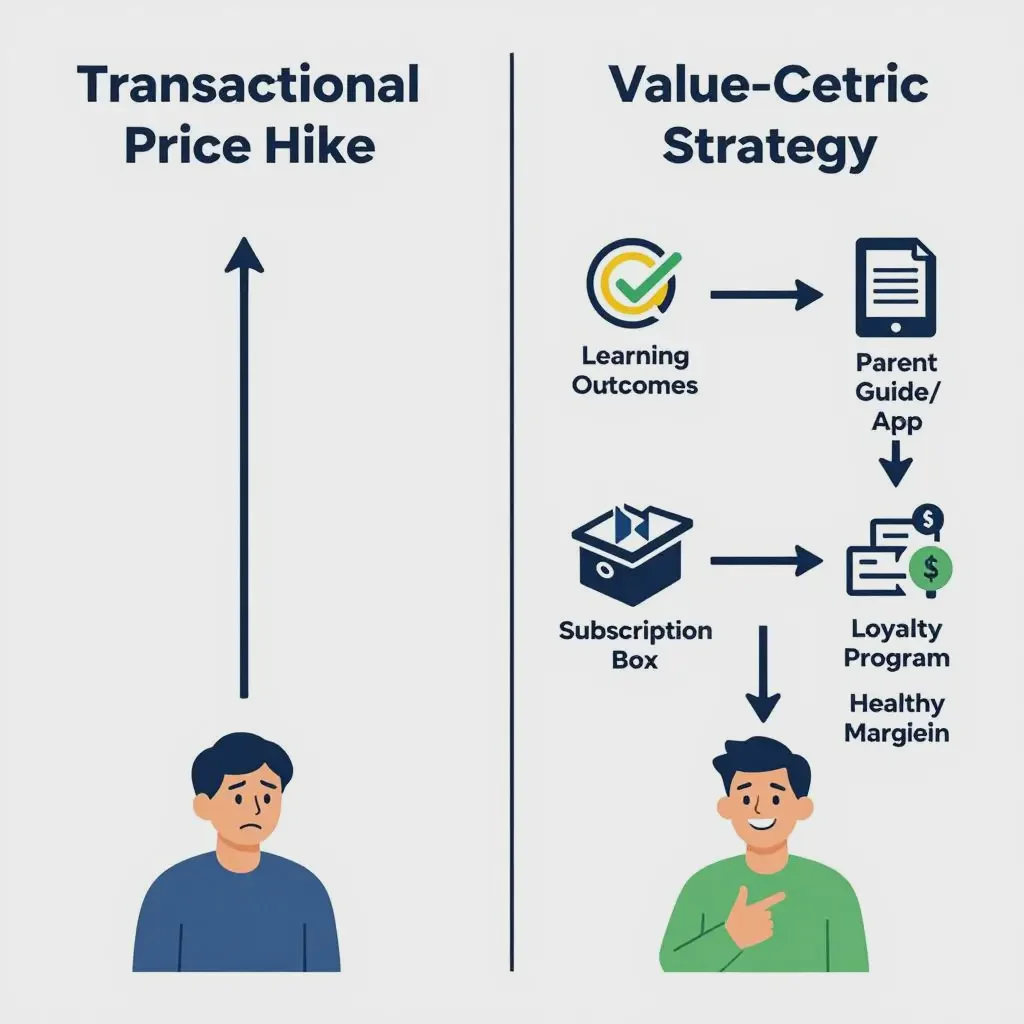

Beyond the List Price: How Can You Implement Value-Centric Pricing?

A knee-jerk price increase can backfire, making your brand seem out of touch. The smarter approach is value-centric pricing—a strategy that justifies price adjustments by reinforcing the superior worth of your product and strengthening the customer relationship.

This involves a fundamental shift from communicating price to articulating unique value. It's about telling a better story, creating new bundles, and building loyalty that transcends a single transaction.

First, enhance your value narrative. Deeply integrate your educational philosophy into marketing. Highlight research-backed benefits, detailed lesson plans included, or the expertise of your designers. Make the "why" behind the cost impossible to ignore. Second, explore new product configurations. Instead of just raising the price of a standalone puzzle, create a "Discovery Series" bundle with multiple expansion packs at a perceived discount. Third, consider subscription or membership models. A monthly STEM kit delivery creates predictable revenue, builds community, and focuses the customer on the experience rather than the unit cost. Finally, practice tiered transparency. For direct-to-consumer sales, consider explaining that "price adjustments reflect our ongoing commitment to using safe, durable materials and ethical manufacturing." This frames the cost as an investment in trust.

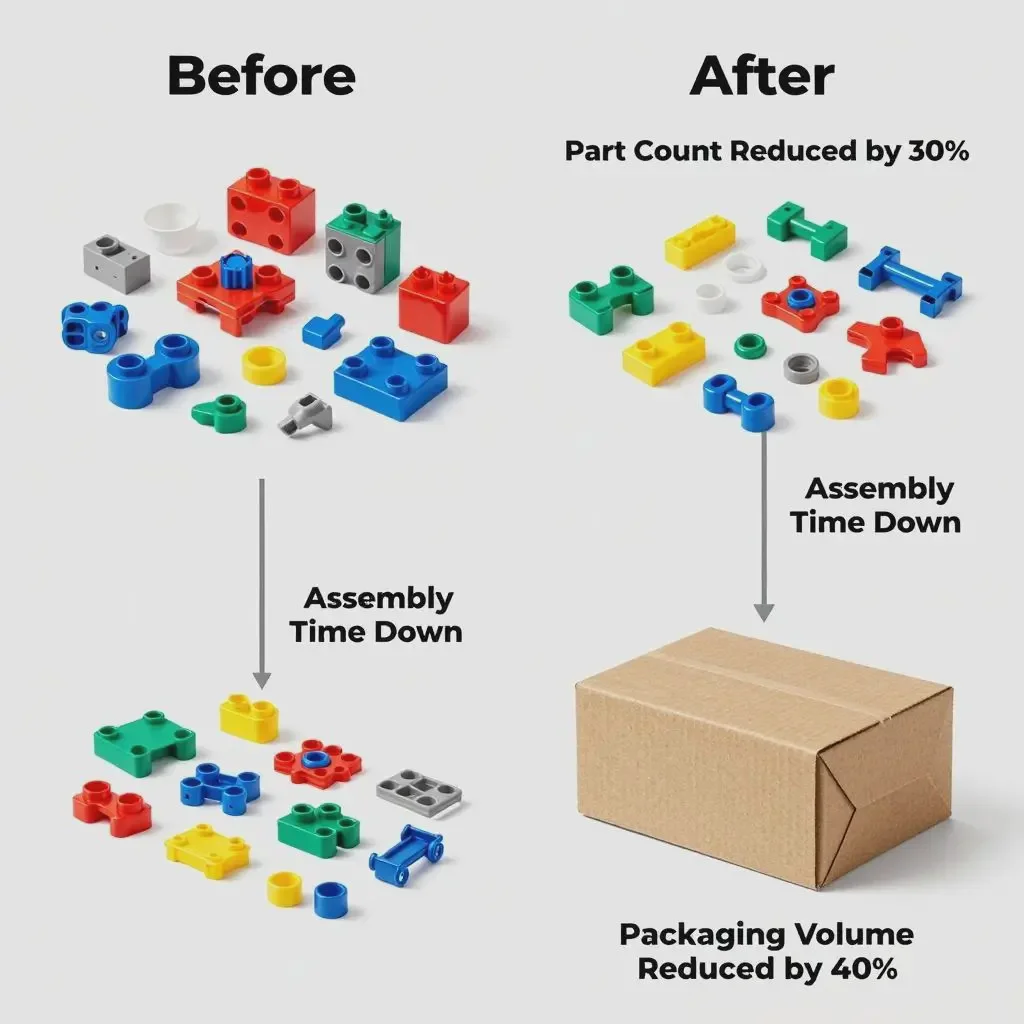

Can You Redesign for Efficiency Without Compromising Quality?

One of the most powerful levers for margin protection lies in the design phase itself. Value Engineering (VE) is a systematic method to improve a product's value by optimizing its function-to-cost ratio. It’s not about cheapening, but about innovating smarter.

A rigorous VE process scrutinizes material selection, component design, manufacturing processes, and packaging to identify savings that do not detract from—and can sometimes enhance—the user experience and product safety.

Engage your design and engineering teams in a VE workshop. Key questions include: Can we use a slightly different grade or recycled content of plastic that meets safety standards but costs less? Can we redesign this component to serve two functions, eliminating a separate part? Can we simplify the mold design to reduce manufacturing time and complexity? Often, the biggest win is in packaging. Switching to right-sized, recycled, or less graphically intensive packaging can significantly cut material and shipping costs (due to lower dimensional weight), while also appealing to eco-conscious consumers. The mantra is "simplify, consolidate, optimize."

How Do You Build a Supply Chain That's Both Cost-Effective and Resilient?

Treating suppliers as mere transactional vendors is a luxury of the past. In an era of volatility, your supply chain relationships are strategic assets. Building a resilient network requires collaboration, diversification, and data-driven planning.

The goal is to shift from a fragile, cost-minimized chain to an agile, partner-powered network. This involves deepening key relationships, exploring strategic nearshoring, and leveraging technology for better visibility and forecasting.

Initiate strategic supplier partnerships with your top manufacturers. Discuss long-term forecasts and explore fixed-price or price-cap agreements for key materials to mitigate spikes. Diversify your sourcing geographically. While not always cheaper upfront, having a vetted supplier in a different region (e.g., Eastern Europe or Mexico alongside Asia) provides a crucial contingency plan against regional disruptions. Invest in supply chain visibility tools. Even basic digital dashboards that track inventory levels, production status, and shipment location help you anticipate delays and manage cash flow better. Finally, collaborate on logistics. Work with partners to consolidate shipments, optimize container space, and plan production cycles to avoid peak shipping seasons. This shared-effort approach turns cost centers into areas of mutual problem-solving.

From Defense to Offense – Building a Future-Proof Brand

The current climate of cost pressure is not a temporary squall; it's a permanent shift in the operational weather. For educational toy brands, the strategies to protect margins must therefore be embedded into the company's core philosophy, moving from short-term defense to long-term strategic offense.

Success will belong to the brands that view this challenge as a catalyst for innovation. By mastering value-centric pricing, you build deeper customer loyalty. By embracing value engineering, you create more efficient, sustainable, and often better-designed products. By forging resilient supply chain partnerships, you gain stability and agility. Collectively, these actions do more than safeguard profitability—they strengthen your brand's value proposition, insulate you from market whims, and position you as a leader in a responsible, thoughtful industry. The ultimate goal is to emerge not just with margins intact, but with a brand that is more intelligent, resilient, and valuable than ever before.