From Breaking Point to Unbreakable: Can Educational Toys Build a Truly Resilient Supply Chain?

From Breaking Point to Unbreakable: Can Educational Toys Build a Truly Resilient Supply Chain?

The educational toy industry has just endured a masterclass in vulnerability. Ports seized, factories silenced, and demand oscillated wildly between frenzied peaks and sudden troughs. The lean, hyper-efficient supply chains that were once a badge of honor became the single point of catastrophic failure, transforming hot products into heartbreaking backorders and eroding years of brand equity. Yet, profound disruption is also the most powerful catalyst for innovation. The pressing question is no longer if the next shock will come, but how brands can move beyond reactive patching to proactively architect supply chains that are intelligent, adaptable, and fundamentally resilient. This article distills the hard-won lessons from recent crises and provides a strategic blueprint for building supply networks that don't just survive, but thrive under pressure.

Modern supply chain resilience transcends having a backup factory. It's a strategic system built on multi-sourced production, intelligent inventory buffers, end-to-end digital visibility, collaborative supplier alliances, and flexible product design—creating a network that can anticipate, absorb, and adapt to disruption.

Building this new model requires a fundamental shift in mindset and operations. Let's deconstruct the journey from fragile to resilient, starting with a diagnosis of past failures, then exploring the core strategic pillars, the enabling role of technology, and the critical human element of partnership.

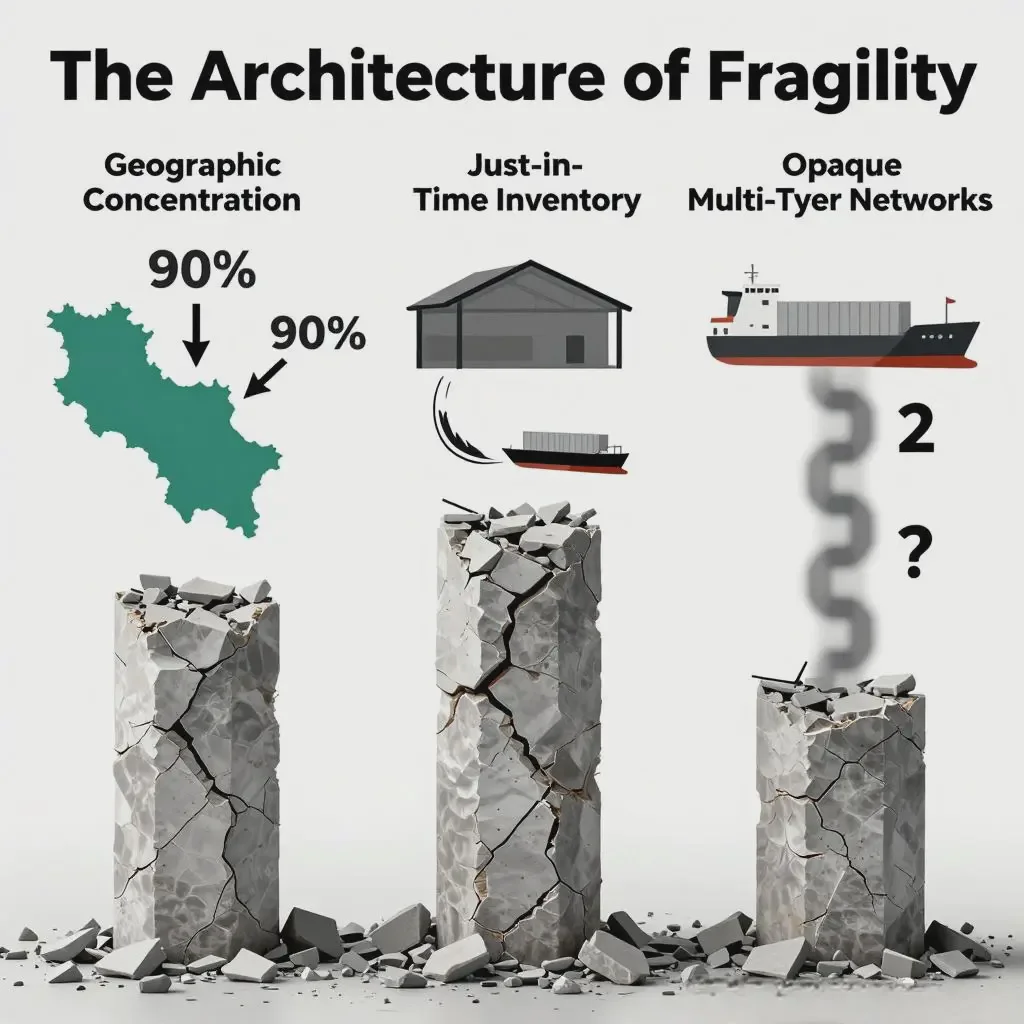

Diagnosis: What Broke? The Three Pillars of Pre-Crisis Fragility

To construct a resilient future, we must first understand the brittle foundations of the past. The pre-disruption toy supply chain was a marvel of cost optimization, but its core principles proved to be crippling vulnerabilities when global stability vanished.

Fragility was engineered into the old model through extreme geographic concentration, a dogmatic adherence to just-in-time inventory, and opaque, multi-tiered supplier networks that created blind spots and inflexibility.

The industry's efficiency was its Achilles' heel. Over-reliance on a single manufacturing superhub meant a regional lockdown could halt global supply. The just-in-time philosophy, which minimized cash tied up in inventory, left no buffer for massive transport delays, leading to empty shelves. Perhaps most critically, brands often had direct relationships only with their final assembly partners. The sources of critical components—specialty plastics, microchips for interactive toys, pigments—were several tiers removed. This lack of visibility meant shortages of a single sub-component, unknown to the brand until it was too late, could stop an entire production line. The system was lean but blind and brittle.

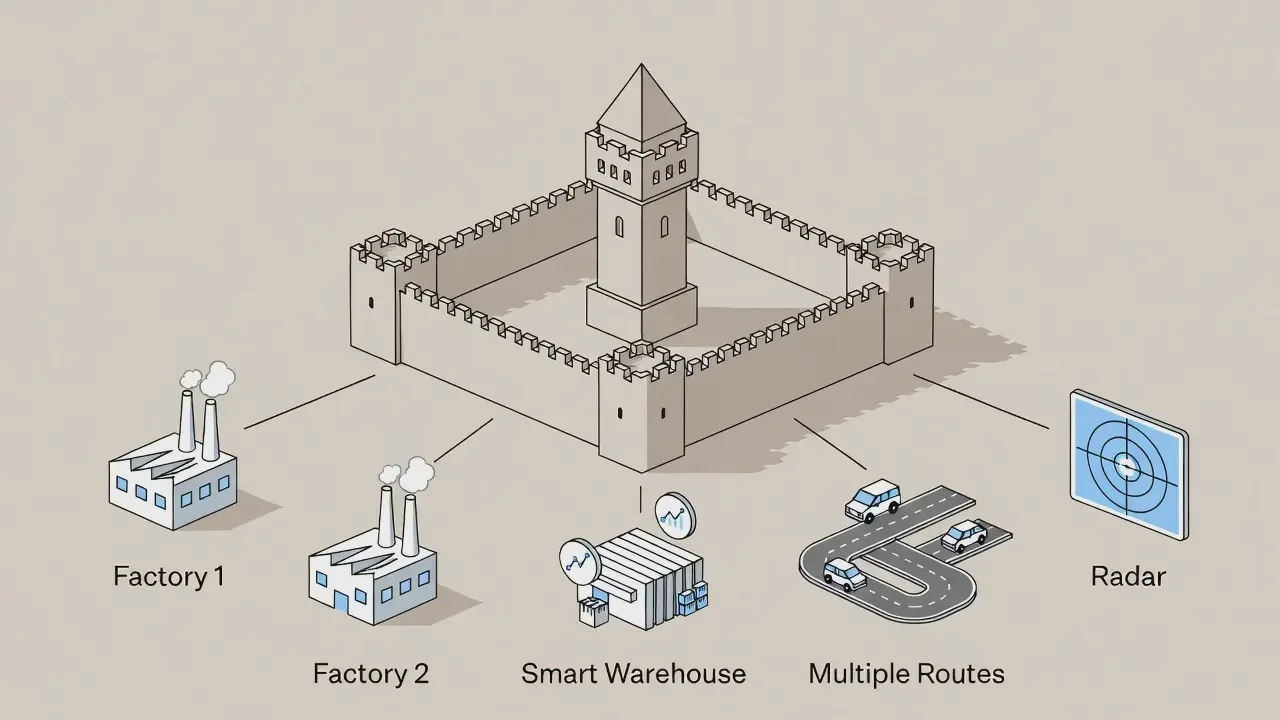

The Resilience Framework: What Are the Five Strategic Pillars?

Resilience is not a single action but an interconnected system of defenses. It replaces singular efficiency with distributed strength, creating optionality and buffers at critical points.

The five pillars are: 1) Network Diversification, 2) Dynamic Inventory Strategy, 3) Logistics Redundancy, 4) Design for Flexibility, and 5) Proactive Risk Intelligence.

This framework moves from theory to action:

Network Diversification ("China + N"): Implement a dual or multi-region sourcing strategy. Maintain primary partners for scale but actively qualify and audit secondary suppliers in different geopolitical and logistical zones. For critical components like batteries or ICs, dual-sourcing is non-negotiable.

Dynamic Inventory Strategy: Move beyond static safety stock. Use data to hold strategic inventory of long-lead, generic materials, and employ postponement strategies—keeping products in a semi-finished, modular state for final assembly or configuration closer to the point of demand.

Logistics Redundancy: Partner with multiple freight forwarders and utilize a portfolio of shipping routes and ports. For high-value or time-sensitive items, pre-negotiate air freight options as a contingency.

Design for Flexibility (DfF): Engineer products with modularity and commonality. Using standardized components across product lines allows production to shift more easily and reduces the number of unique, risky SKUs.

Proactive Risk Intelligence: Dedicate resources to continuously monitor not just your Tier-1 suppliers, but also geopolitical, climate, and logistical risks that could impact the entire network.

The Digital Nervous System: How Can Technology Enable Foresight and Agility?

Strategic pillars provide the structure, but a digital nervous system provides the intelligence and reflexes. Technology transforms resilience from a theoretical concept into a real-time, actionable capability.

Leverage Supply Chain Control Towers, AI-powered demand sensing, IoT for real-time tracking, and digital twin simulations to gain visibility, predict disruptions, and model responses with precision.

Key technologies create a responsive network:

The Control Tower: A centralized digital command center aggregates data from ERPs, suppliers, and logistics providers, offering a single pane of glass for end-to-end visibility from raw material to customer doorstep.

AI & Advanced Analytics: These tools move demand planning beyond historical sales. By analyzing social sentiment, search trends, and economic indicators, they enable predictive demand sensing, allowing for weekly or even daily adjustments to production plans.

IoT & Real-Time Tracking: Sensors on shipments provide live data on location, temperature, and handling. This prevents loss and allows for dynamic re-routing in response to delays.

Digital Twins: A virtual replica of your physical supply network allows you to run "what-if" stress tests (e.g., "What if a key supplier shuts down for 30 days?") in a risk-free environment, validating and refining contingency plans before a real crisis hits.

Beyond Contracts: How Do You Forge a "Resilience Alliance" with Suppliers?

The most advanced technology and elegant strategy fail without trust and collaboration. Lasting resilience is co-created; it requires moving from transactional buyer-supplier relationships to strategic, inter-dependent partnerships.

Build resilience alliances through long-term commitments & shared planning, joint investment in capacity, transparent communication protocols, and collaborative risk management.

This represents a cultural and operational shift:

From PO to Partnership: Offer key suppliers multi-year volume commitments in exchange for dedicated capacity, priority during shortages, and collaborative cost management. Share your sales forecasts and risk assessments to create a single, shared plan.

Co-Investment in Capability: Consider joint investments to improve a supplier's resilience—helping them secure backup power, finance a second molding machine, or achieve a critical sustainability certification. This strengthens your entire ecosystem.

Transparent Crisis Communication: Co-develop clear communication protocols for disruptions. Define escalation paths, points of contact, and data-sharing agreements before a crisis, ensuring a coordinated, fact-based response.

Joint Business Continuity Planning: Work with top-tier suppliers to stress-test their own sub-tier networks and develop their contingency plans. Your network is only as strong as its weakest node.

Conclusion

The age of the fragile, hyper-lean supply chain is over for the educational toy industry. The recent crises were not anomalies but a brutal exposure of a system optimized for a world of stability that no longer exists. The path forward demands a new paradigm built on distributed

Building resilience is not a cost to be minimized but a strategic capability to be invested in. It is the foundation that ensures you can fulfill promises to customers when competitors cannot, protects your brand from the reputational damage of constant stock-outs, and enables agile innovation. By learning from the fractures of the past, implementing a holistic strategic framework, harnessing technology for foresight, and forging genuine alliances with suppliers, educational toy companies can construct supply chains that are a source of enduring competitive advantage. In an unpredictable world, resilience is the ultimate currency.

[External links recommendation]: