From Breakage to Breakthrough: Can Educational Toy Brands Build Unbreakable Supply Chains?

From Breakage to Breakthrough: Can Educational Toy Brands Build Unbreakable Supply Chains?

Opening Paragraph.

The last few years have delivered a harsh, hands-on curriculum in supply chain management for the educational toy industry. Ports clogged, factories shuttered, demand skyrocketed, and then vanished. The once-invisible backbone of global commerce became the primary point of failure, turning bestsellers into backorders and eroding hard-won customer trust. But disruption is also the greatest teacher. For forward-thinking brands, the question is no longer if another shock will come, but how to transform reactive fragility into proactive, strategic resilience. This article decodes the hard lessons from recent crises and charts a practical roadmap for building educational toy supply chains that aren't just efficient, but intelligent, adaptable, and truly unbreakable.

Snippet Paragraph.

Building resilience requires moving beyond single-factory dependency and bulk inventory. The new model is built on supplier diversification, strategic "smart" inventory, end-to-end digital visibility, and deep supplier partnerships to create a network that can anticipate stress, absorb shocks, and adapt swiftly.

Transition paragraph.

Transforming a linear, cost-optimized chain into a dynamic, resilient network is a multi-layered endeavor. It requires a clear diagnosis of past failures, a rebuild of core operational strategies, a embrace of enabling technology, and a fundamental shift in how partners work together. Let's build this new model layer by layer.

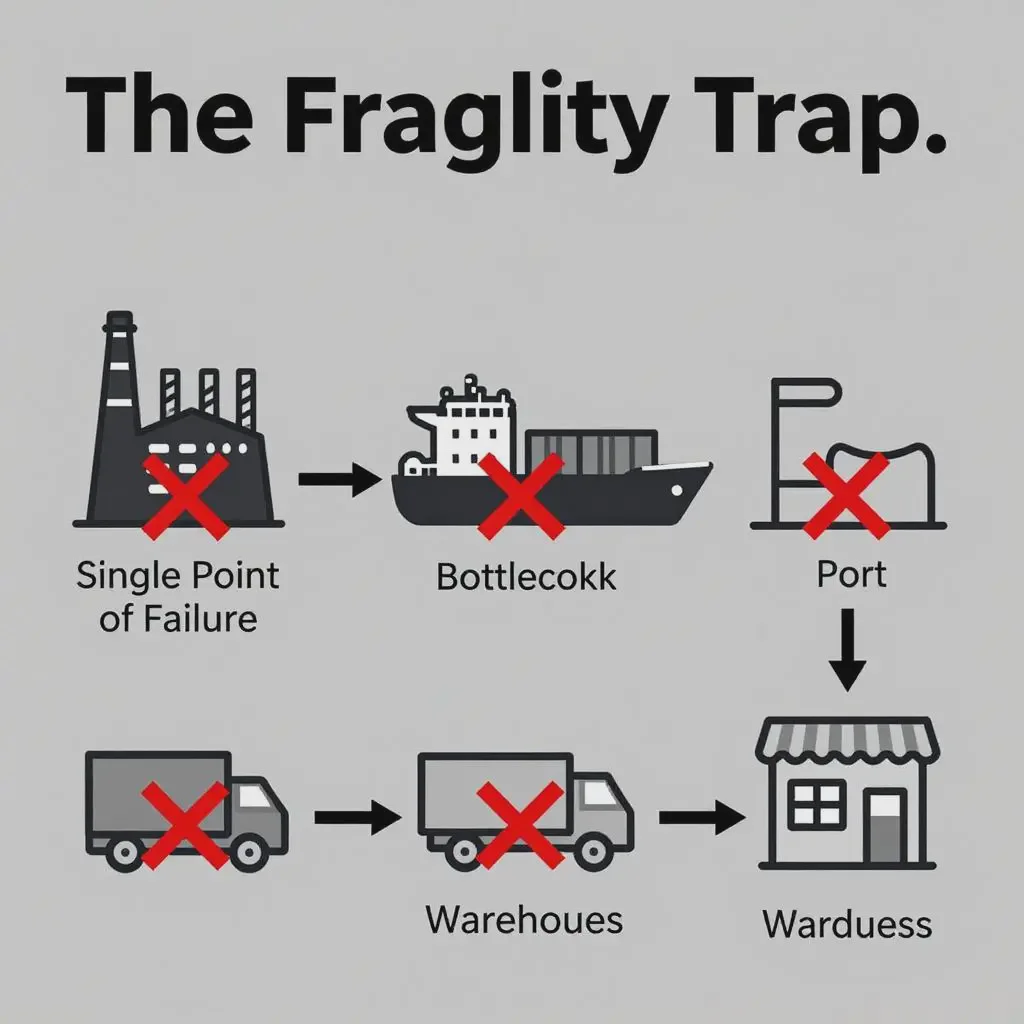

Lesson 1: What Did We Get Wrong? The Fragile Foundations of the Old Model?

To build something stronger, we must first understand why the old structure crumbled under pressure. The pre-disruption supply chain for toys was a masterpiece of lean efficiency, but its strengths became fatal vulnerabilities when the world changed overnight.

The old model failed due to extreme geographic concentration, just-in-time inventory dogma, opaque multi-tier networks, and rigid, long-lead production cycles that couldn't flex with volatile demand.

The Concentration Gamble: Over-reliance on a single geographic region (e.g., the Pearl River Delta) for >80% of production meant a regional lockdown halted the entire industry. This was compounded by dependency on single factories for key components.

Just-in-Time Meets Just-Too-Late: The pursuit of minimal inventory saved cash but left no buffer for surges in demand or transport delays. When ships waited weeks to dock, store shelves emptied with no buffer stock to replenish them.

The Black Box Effect: Brands often had visibility only to their Tier-1 assembler. The sources of critical materials—electronics, specialty plastics, pigments—were several tiers removed, making it impossible to foresee shortages or switch sources quickly.

Inflexible Production: Long lead times for molding, tooling, and complex assembly meant supply chains couldn't pivot quickly when demand shifted from, say, outdoor toys back to STEM kits, creating massive mismatches.

The Resilience Playbook: What Are the 5 Pillars of an "Unbreakable" Chain?

Resilience is not a single action but a system of interconnected defenses. It's about creating optionality, building buffers intelligently, and designing for flexibility from the outset.

The five pillars are: 1) Multi-Sourced & Regionalized Production, 2) Differentiated "Smart" Inventory, 3) Logistics Diversification, 4) Product & Process Design for Flexibility, and 5) Dynamic Risk Monitoring.

1. Multi-Sourced Production: Implement a "China + N" strategy. Keep high-volume, stable items in your primary region, but develop vetted, certified capacity in a secondary region (e.g., Vietnam, Mexico for the Americas) for strategic or fast-turn items. Dual-source critical components like chips or motors.

2. Differentiated "Smart" Inventory: Ditch one-size-fits-all safety stock. Hold strategic inventory of long-lead, generic materials (plastic resins, standard electronics). Use dynamic buffers for finished goods based on predictive analytics. Embrace postponement: keep semi-finished, modular products and do final assembly/configuration locally based on actual demand.

3. Logistics Diversification: Partner with multiple freight forwarders. Utilize a mix of ports (East vs. West Coast). For high-value, time-sensitive goods, have air freight as a contingency option. Explore regional warehousing to shorten last-mile delivery.

4. Design for Flexibility: Use modular designs with common components across product lines. This allows you to shift production capacity more easily and reduces unique SKUs. Simplify products where possible to reduce component count and supplier dependency.

5. Dynamic Risk Monitoring: Continuously monitor geopolitical, climate, and logistics data. Have a dedicated team or use software to track potential disruptions and trigger pre-defined contingency plans.

The Tech-Enabled Future: How Can Data and AI Turn Guesswork Into Foresight?

Pillars provide structure, but data and intelligence provide the nervous system. The next leap in resilience comes from replacing reactive guesswork with proactive, data-driven foresight across the entire network.

Leverage Supply Chain Control Towers, AI-driven demand sensing, IoT tracking, and digital twin simulations to gain real-time visibility, predict disruptions, and model responses before a crisis hits.

The Control Tower: A centralized digital platform that aggregates data from ERP, suppliers, logistics partners, and IoT sensors. This provides end-to-end visibility, showing exactly where every order and component is in real time—from sub-supplier to warehouse.

AI for Demand Sensing & Prediction: Move beyond historical sales data. Use AI to analyze real-time signals—social media trends, search traffic, weather patterns, economic indicators—to create more accurate, short-term demand forecasts and adjust production plans weekly or daily.

IoT for In-Transit Visibility: Smart tags on containers and pallets provide real-time location, temperature, and shock data. This prevents "lost" shipments and allows for dynamic rerouting if a delay occurs.

Digital Twins for Simulation: Create a virtual replica of your supply network. Use it to run "what-if" scenarios: What if a typhoon hits Shenzhen? What if demand spikes 300%? Model the impact and test the effectiveness of different response plans in seconds, without real-world cost or disruption.

The Human Factor: How Do You Build a "Resilience Alliance" with Suppliers?

Technology and strategy are useless without trust and collaboration. The most resilient networks are those where brands and suppliers move from transactional relationships to strategic partnerships, sharing both risks and rewards.

Foster resilience alliances through long-term commitments & shared forecasting, joint business continuity planning, co-investment in capacity/capability, and transparent communication protocols.

Sub-heading 4 dive deeper paragraph.

Beyond the PO: Offer key suppliers multi-year volume commitments in exchange for dedicated production lines, priority during shortages, and collaborative cost management. Share your demand forecasts and even risk assessments with them, moving from a "purchase order" to a "shared plan" model.

Joint Business Continuity Planning (BCP): Work with top suppliers to develop their own BCPs. Help them identify their single points of failure (power, sub-components) and develop backups. A resilient brand is only as strong as its weakest supplier link.

Co-Invest for Mutual Gain: Consider joint investments—in a supplier's new molding machine, in quality control software, or in sustainability certifications. This builds capability, loyalty, and a stronger overall ecosystem.

Establish Clear Communication Protocols: Define exactly how you will communicate during a crisis. Who are the points of contact? What data will be shared hourly/daily? Having this "circuit breaker" plan in place prevents panic and misinformation when seconds count.

Conclusion

The era of the fragile, hyper-lean, and opaque supply chain is over for the educational toy industry. The disruptions of recent years were not anomalies but stress tests, revealing that pure efficiency is a brittle strategy. The path forward is one of robustness, visibility, and collaboration.

Building resilience is not an optional cost center; it is the new foundation for brand survival and growth. It is the capability that ensures you can meet demand when competitors cannot, that protects your reputation from the damage of constant stock-outs, and that allows you to innovate and adapt with speed. By learning from past failures, implementing a multi-pillar strategic playbook, harnessing technology for foresight, and forging true alliances with suppliers, educational toy brands can do more than survive the next disruption. They can build supply chains that are a source of unbreakable competitive advantage, turning vulnerability into their greatest strength.