Smart Toy Supply Chain Integration: Hardware, Software, and IoT Solutions

Smart Toy Supply Chain Integration: Hardware, Software, and IoT Solutions

The evolution of smart toys has fundamentally transformed the toy supply chain. No longer a linear process of sourcing plastic and packaging, it's now a complex integration of hardware manufacturing, software development, and cloud-based IoT ecosystems. Success in this dynamic market requires a seamless, synchronized approach across all three pillars. This guide provides a comprehensive roadmap for integrating hardware, software, and IoT solutions to build a resilient, efficient, and innovative smart toy supply chain.

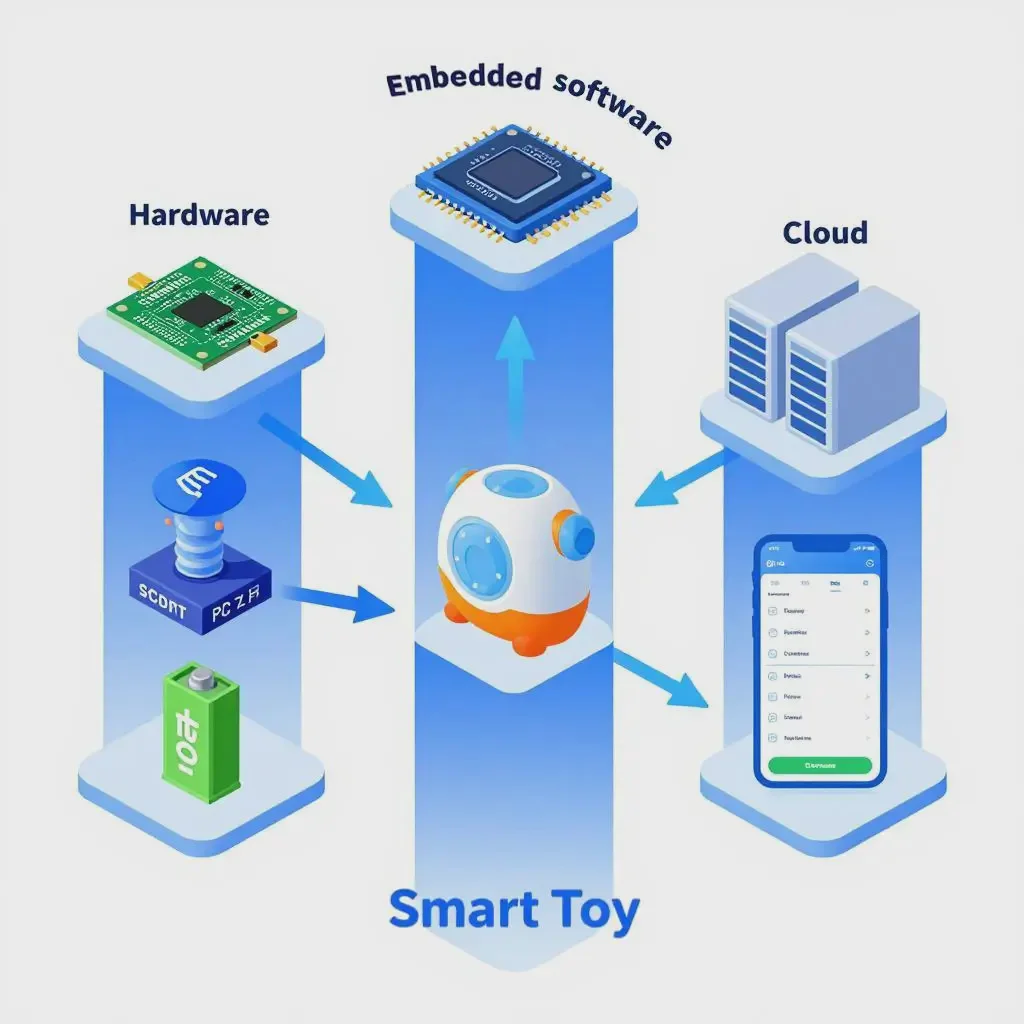

Part 1: The Trifecta of Smart Toy Development

A modern smart toy is the sum of three interdependent components:

The Hardware: The physical product (sensors, microprocessors, actuators, casing, batteries).

The Embedded Software & Firmware: The code that runs on the toy’s microcontroller, managing inputs, outputs, and basic functions.

The IoT Cloud Platform & Applications: The backend servers, databases, APIs, and companion mobile apps that enable data exchange, advanced features, and content updates.

Failure to plan for the integration of these elements from the outset leads to cost overruns, delayed launches, and poor user experiences.

Part 2: Strategic Hardware Sourcing & Integration

Hardware forms the tangible foundation. Its sourcing requires new considerations.

Component Sourcing Strategy:

Strategic Dual Sourcing: For critical electronic components (chips, sensors), identify multiple vetted suppliers to mitigate shortage risks.

Modular Design: Develop hardware with modular components. This allows for easier upgrades, repairs, and adaptation of the base platform for future product variants.

Long-Term Component Forecasting: Work with suppliers on 12-18 month forecasts for key ICs and batteries, locking in supply ahead of production cycles.

Hardware-Software Co-Design (The Critical Phase):

Define the Tech Stack Early: Select the core microcontroller unit (MCU), connectivity module (Bluetooth Low Energy, Wi-Fi), and sensors in tandem with your software team. The hardware must have adequate processing power and memory for the intended features and future updates.

Prototype Rigorously: Move beyond 3D-printed form models to fully functional engineering prototypes (EVT - Engineering Validation Test) that test the integration of PCBAs, firmware, and mechanical parts.

Design for Manufacturing (DFM) & Testing (DFT): Collaborate with your OEM to design hardware for automated assembly and include test points on the PCB for efficient firmware flashing and quality control.

Part 3: Agile Software & Firmware Development Lifecycle

Software development must run in parallel with hardware, not sequentially.

Adopt a Phased, Agile Approach:

DVT (Design Validation Test): Develop and test core firmware functionalities on prototype hardware. Validate user interactions, sensor accuracy, and power management.

PVT (Production Validation Test): Finalize the production-grade firmware on units from the actual production line. This phase locks the software for mass production.

Post-Launch OTA Updates: Plan for the firmware to support Over-The-Air (OTA) updates from day one. This allows bug fixes, security patches, and feature additions after the toy is in consumers' hands.

Security by Design:

Embed security at the firmware level. This includes secure boot, encrypted data storage on the device, and secure communication protocols with the app/cloud.

Part 4: Building a Scalable & Secure IoT Backbone

The cloud platform is the "brain" that enables smart features and longevity.

Choose Your Stack: Decide between building a custom cloud infrastructure or leveraging specialized IoT Platforms as a Service (PaaS) like AWS IoT Core, Google Cloud IoT, or Azure IoT Hub for faster, more secure deployment.

API-First Design: Build robust, well-documented APIs for communication between the toy, the cloud, and companion apps. This ensures flexibility for future third-party integrations (e.g., educational content partners).

Data Pipeline Design: Plan how you will handle, process, and store data (play patterns, preferences) responsibly and in compliance with regulations like COPPA (Children's Online Privacy Protection Act) and GDPR.

Companion App Development:

The app should enhance the play experience, not be a bottleneck. Ensure intuitive pairing (e.g., simple Bluetooth pairing), offline functionality where possible, and a clear value proposition for parents.

Part 5: End-to-End Supply Chain Synchronization

Integration demands synchronization across every stage.

Pre-Production:

Joint Development Teams: Create cross-functional teams with members from hardware engineering, software development, cloud architecture, and procurement.

Unified Project Management: Use integrated tools (e.g., Jira with hardware milestones) to maintain a single source of truth for timelines, with dependencies between PCB fabrication, firmware builds, and app store submissions clearly mapped.

Production & Fulfillment:

Flashing & Provisioning: Integrate firmware flashing and IoT device provisioning (assigning a unique cloud identity) directly onto the SMT assembly line or in a dedicated post-assembly station.

Integrated QC: Quality checks must validate hardware functionality and software integrity (e.g., firmware version check, sensor calibration, successful cloud handshake in final packaging).

Logistics with Digital Twins: Consider using IoT-enabled logistics to monitor shipments of high-value smart toys, tracking location and environmental conditions (temperature, humidity).

Post-Launch & Lifecycle Management:

Monitor Ecosystem Health: Use cloud dashboards to monitor toy connectivity rates, feature usage, and error reports in real-time.

Manage Product Lifecycle: Plan for orderly sunsetting of products, including providing final security updates and managing cloud service dependencies to avoid creating e-waste.

Part 6: Critical Compliance & Risk Mitigation

Data Privacy & Security: Implement end-to-end encryption, anonymize data, and maintain transparent privacy policies. Regular third-party security audits are essential.

Regulatory Convergence: Smart toys must comply with both toy safety standards (EN71, ASTM F963) and electronic/radio equipment directives (FCC, RED).

Supply Chain Transparency: Use technology (like blockchain-based tracking for critical components) to ensure component authenticity and ethical sourcing.

Conclusion: The Integrated Advantage

The future of toys is connected. Winning in this space requires abandoning traditional, siloed supply chain models in favor of a holistic, integrated approach. By co-developing hardware, software, and IoT solutions within a synchronized supply chain, companies can achieve:

Faster Time-to-Market through parallel development.

Superior Product Quality with fewer integration failures.

Enhanced Long-Term Value through updateable, platform-based toys.

Stronger Competitive Moats built on seamless user experiences and robust ecosystems.

Viewing your smart toy not just as a product, but as a unified, living system, is the key to unlocking sustainable innovation and profitability in the digital play revolution.