Safety First, Margin Second? Finding a Profitable Path Through Global Toy Regulations

Safety First, Margin Second? Finding a Profitable Path Through Global Toy Regulations

For any toy entrepreneur or brand manager, few statements are as simultaneously true and terrifying as "safety is non-negotiable." The regulatory frameworks governing toys—ASTM F963 in the US, EN71 in the EU, AS/NZS ISO 8124 in Australia—exist for the noblest of reasons: protecting children. Yet, for businesses, they represent a formidable gauntlet of testing costs, documentation hurdles, and timeline delays that can swiftly erode profit margins before a single toy sells. This creates a seemingly impossible tension: how do you uphold an uncompromising commitment to safety while still running a viable, profitable business?

The most successful toy companies reframe the challenge. They stop viewing compliance as a tax on creativity and start treating it as a core component of product development and brand strategy. By integrating regulatory requirements from the design phase, strategically planning market entry, and leveraging compliance as a competitive marketing advantage, it's possible to build a profitable business that puts safety genuinely first—without putting margins a distant second.

Navigating this path requires moving from reactive cost-bearing to proactive value-creation. It's about smart strategy, not just stubborn spending. Let's map the route from regulatory burden to business asset.

To transform compliance from a cost center into a strategic pillar, we need to examine four critical dimensions: the true financial anatomy of compliance, strategic planning for market entry, efficient process management, and the ultimate reframing of safety into a sales tool.

The Compliance Cost Breakdown: Where Does the Money Actually Go?

Before you can manage costs, you must understand them. The price tag for bringing a compliant toy to market isn't a single fee; it's a cascade of interconnected expenses that begin at the drawing board and continue through the product's lifecycle.

The direct costs of lab testing and certification are just the tip of the iceberg. The full financial picture includes pre-compliance design consulting, material pre-screening, prototype iterations for failed tests, technical file documentation, ongoing production batch testing, and the hidden overhead of internal staff time managing the entire process. A $5,000 lab bill can easily mask a $20,000 total project cost.

Consider a typical plush toy with electronics. The bill might include: Chemical testing for every unique material (fabric, thread, filling, plastic eyes, PCB) against heavy metal and phthalate limits (~$400-800 per material). Physical/mechanical testing for small parts, seam strength, and sound levels (~$1,500). Electrical safety testing for batteries and circuits (~$2,000). Then, if marketing to both the US and EU, nearly double it, as while some tests overlap, many do not. A single failure—say, a seam that tears below the required force—requires a redesign, new prototypes, and a partial retest, adding weeks and thousands more. The most significant cost savings come from preventative spending: investing in expert design review and material vetting before the lab sees your product.

Strategic Market Sequencing: Which Regulations Give You the Best ROI?

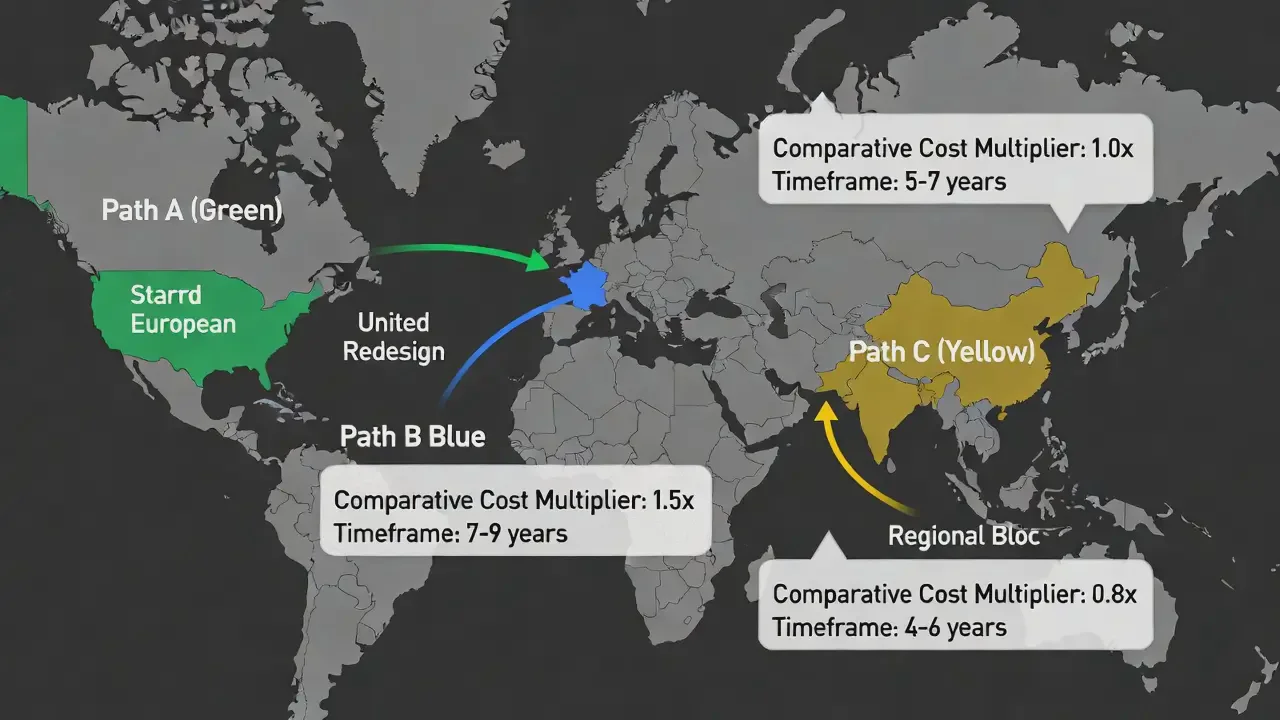

Not all markets are created equal in terms of regulatory complexity, cost, and sales potential. A strategic, phased approach to global expansion can dramatically improve your return on compliance investment and manage cash flow.

A "compliance-first" market entry strategy prioritizes launching in markets where achieving certification provides the greatest leverage for subsequent expansion. Often, designing for the strictest standards first (typically the EU's EN71) is more cost-effective in the long run, as it creates a robust product that can often be adapted for less stringent markets with minimal additional testing.

The golden rule is: It's cheaper to design up than test down. If your toy passes the EU's rigorous chemical migration tests (EN71-3), it will almost certainly pass the US's. The reverse is not true. Therefore, your first compliance investment should target your most demanding target market. For many, this is the EU. The ROI comes from:

Eliminating Redundant Redesign: One robust design vs. multiple market-specific versions.

Leveraging Test Report Overlap: Accredited labs can use portions of EU test data for US submissions, reducing duplicate fees.

Building a Stronger Brand Narrative: Starting with a reputation for meeting high standards makes entry into other markets easier with retailers and consumers.

The strategy isn't just about geography but also product category. Entering a new market with a simple, low-risk product category (e.g., wooden blocks) to establish your compliance pipeline is smarter than leading with a complex, high-risk electronic toy.

The Efficiency Playbook: How Can You Streamline Without Cutting Corners?

Efficiency in compliance isn't about skipping tests; it's about optimizing the process to avoid delays, reduce errors, and consolidate efforts. This is where operational excellence directly protects your margin.

Streamlining hinges on vertical integration of compliance into your product development lifecycle, from material sourcing to packaging design. Key tactics include creating a standardized internal pre-check system, using component-level certifications, batch testing similar products together, and building long-term partnerships with a knowledgeable testing lab.

Implement these proven efficiency drivers:

Standardized Material Library: Work with suppliers who provide raw materials with existing certifications (e.g., REACH-compliant plastics, OEKO-TEX® certified fabrics). This eliminates the need and cost to test each material yourself.

Family or Group Testing: If you're launching a line of similar dolls with different outfits, test the most complex/varied version as the "parent model." Simpler variants can often be certified under its umbrella at a fraction of the cost.

Digital Document Management: Use a centralized cloud system for all certificates, test reports, and technical files. This cuts the time staff spend searching for documents during audits or retailer requests from hours to minutes.

Proactive Lab Partnership: Don't just send samples to a lab; engage their technical team during the design phase. A few hours of consulting can prevent a failure that costs weeks and thousands of dollars.

The goal is to make compliance a predictable, managed line item rather than a source of constant surprises.

From Cost to Advantage: Can Safety Compliance Actually Drive Sales?

In an era where parents are more informed and concerned than ever, demonstrated safety is a powerful differentiator. The cost of compliance can be offset—and even surpassed—by its value in marketing, brand positioning, and retailer relationships.

Compliance should be visibly woven into your brand story. It transforms from a back-office expense into a front-facing marketing asset. This means prominently displaying certification marks on packaging, creating transparent content about your safety journey, and training sales teams to articulate your standards as a key benefit over cheaper, non-compliant competitors.

Consider safety as a feature, not a footnote. Market it:

To Retailers: A complete, easily accessible technical file makes you a lower-risk supplier. It speeds up their onboarding process and can be the deciding factor in getting shelf space over a competitor with vague compliance.

To Consumers: Use your website and social media to educate. A short video showing a seam strength test or explaining what the CE mark really means builds immense trust. In a survey, 68% of parents said third-party safety certifications influence their purchase.

For Premium Pricing: You cannot compete on price with non-compliant manufacturers. Don't try. Compete on trust, quality, and transparency. Your compliance investment justifies a price point that supports healthy margins and signals quality to consumers.

The ultimate reframe is to view every dollar spent on compliance as an investment in brand equity, customer trust, and market access—assets that appreciate over time and drive sustainable profitability.

Conclusion

The dichotomy between "Safety First" and "Margin Second" is a false choice for the strategic toy business. It arises from viewing regulations as an external imposition rather than an integral framework for responsible and commercial success.

The profitable path is paved with intention. It begins with a clear-eyed understanding of full compliance costs and continues with a strategic market entry plan that maximizes the leverage of your testing investments. It is sustained by operational efficiency that embeds compliance into your workflow, and it is ultimately secured by the courageous decision to market your safety standards as a core competitive advantage. In doing so, you build more than a compliant product line; you build a reputable, resilient brand. The most successful toy companies understand that in today's market, true safety isn't a cost center—it's the very foundation of a lasting and profitable business.